We’ve helped customers globally to increase their uptime, convert their operations into Fill4Life™ systems and save them money in our documented case studies.

Case Studies to Repair your Oil, Boost your Uptime and ROI

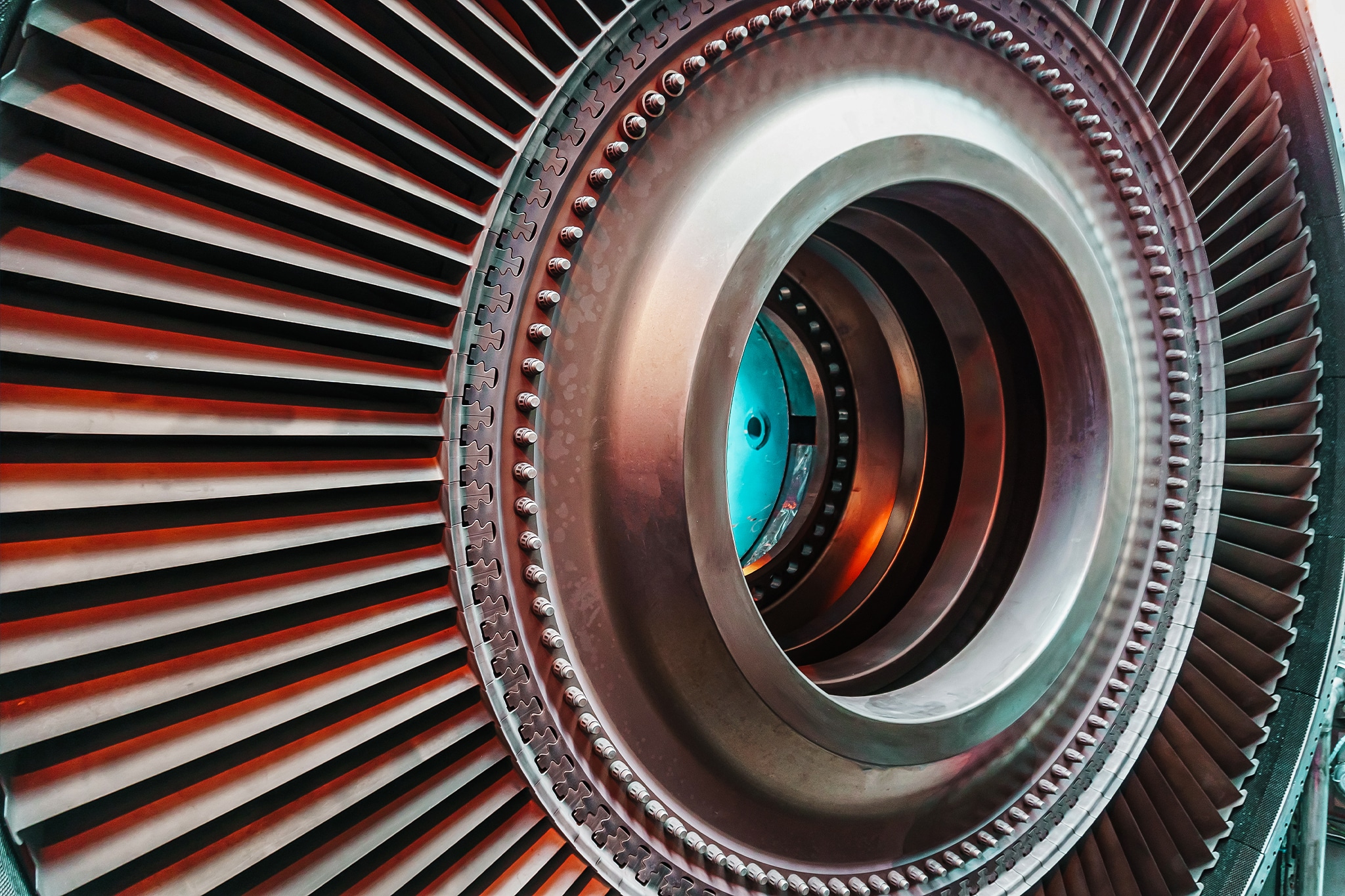

Increasing turbine availability for Australian power generator

More details

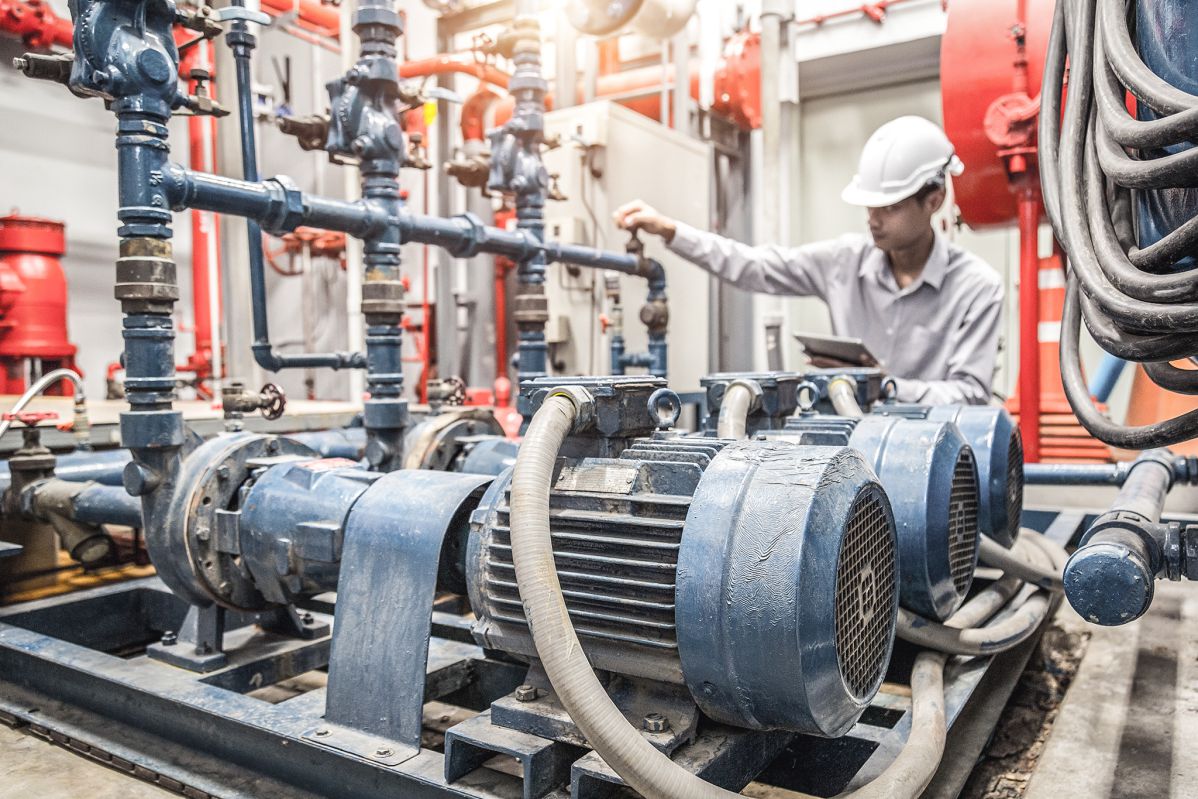

Cooling bearing temps and extending oil life at nitric acid plant

More details

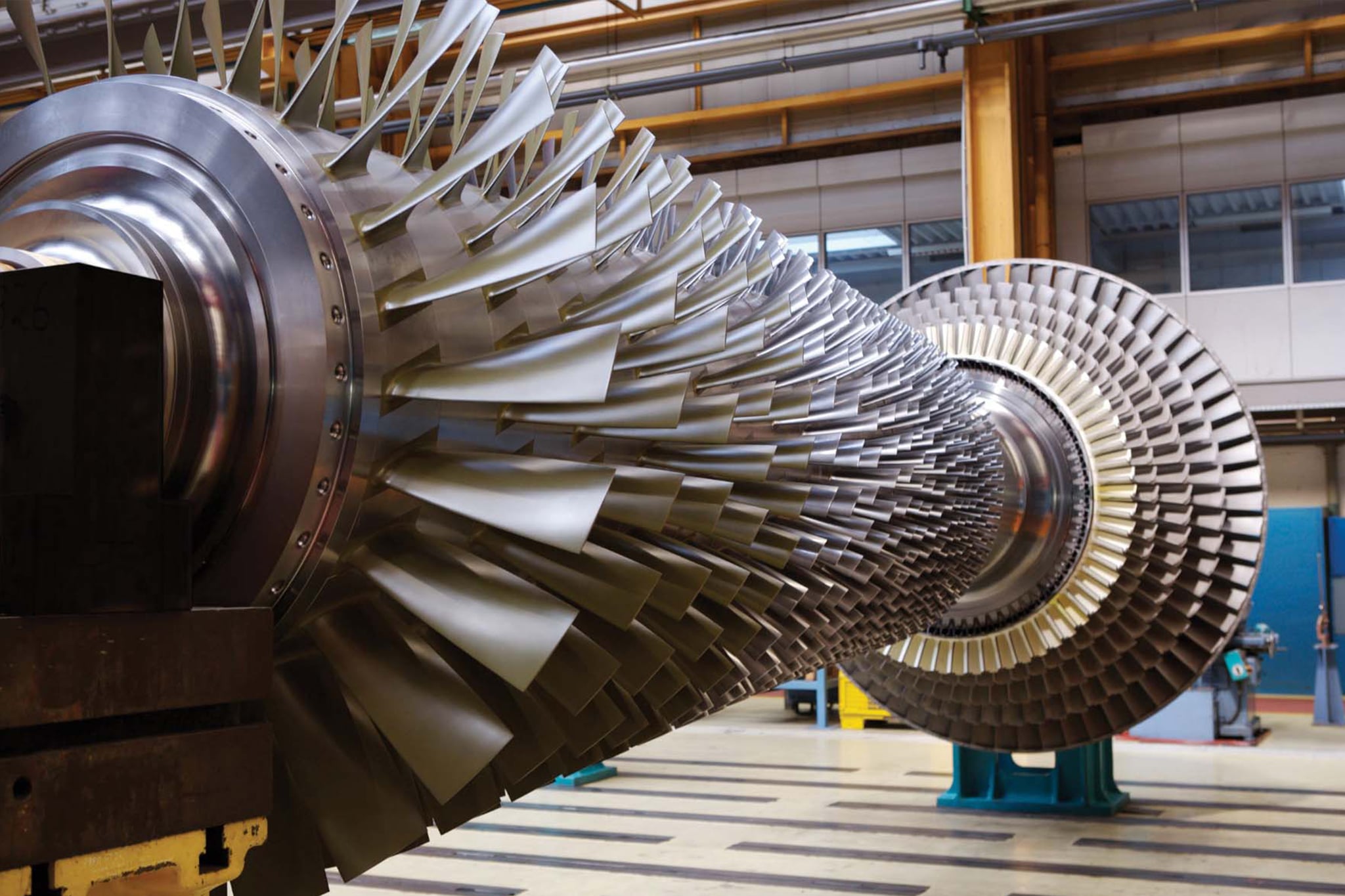

Extending oil life and improving reliability in Turkey

More details

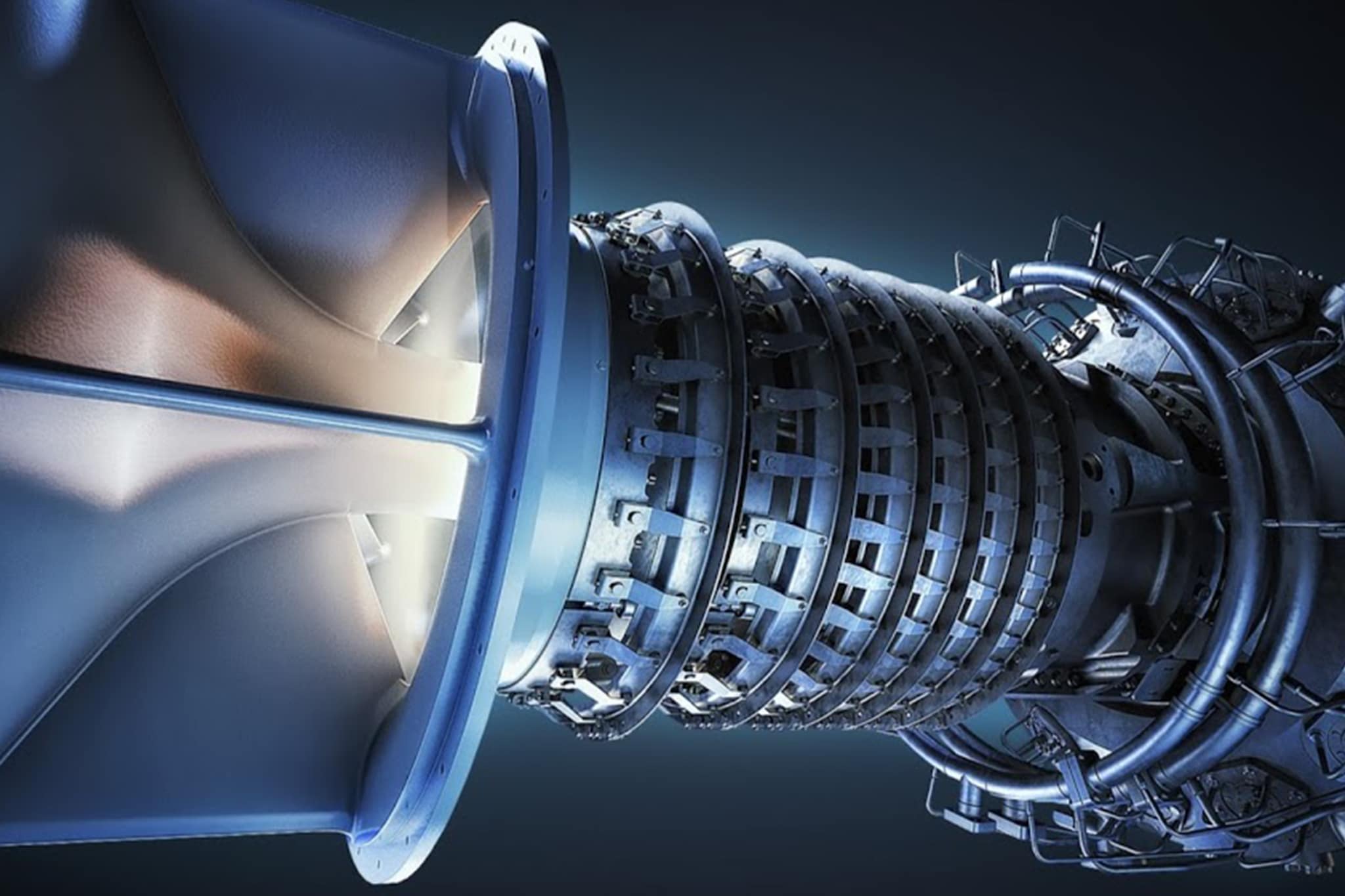

Mitigating potential downtime for a prominent oil and gas company

More details

Solvancer®-based technology helps refinery avoid a major shutdown

More details

Mobil™ Solvancer® Helps Chemical Company Extend Compressor Life

More details

Mobil™ Solvancer® Helps New Jersey Power Plant Save $104K

More details

Minimizing Downtime at Qatari Oil and Gas Company

More details

Eliminating Flushing Saves Chemical Production Plant in Belgium

More details

Petrochemical Plant in China Saves Big Boosting Compressor Load Capacity

More details

Eliminating Flushing Yields Financial Rewards for a Spanish Paper Plant

More details

Eliminating Deposits and Improving Reliability in Italy

More details

Optimizing Maintenance Costs and More at a German Power Plant

More details

Mitigating Downtime for a Tissue Manufacturer

More details

Prolonging Oil Life for a Major Offshore Operator in Qatar

More details

Solving Rapid Filter Fouling and High Varnish at Polish Refinery

More details

Extension of Equipment Oil Life for a Major Chemical Company in Qatar

More details

Reduction of Elevated Thrust and Axial Bearing Temperatures in Qatar

More details

Elimination of Downtime at Truck Manufacturing Plant

More details

Eliminating downtime associated with flushing for a Major Offshore Oil Company

More details

Major Petrochemical Company Extends Oil Life for compressors

More details

Major Automobile Manufacturer Improves Efficiency

More details

Major Chemical Company avoids decrease in production output

More details

Elimination of gearbox deposits at Paper Production Plant

More details

Eliminating downtime and flushing costs for a Natural Gas Supplier

More details

Reduction of axial bearing deposits at Gas Treatment Plant

More details

Reduction of bearing temperatures at a Chemical Plant

More details

Extending the oil life of a gas compressor at an Air Separation Plant

More details

Side by Side comparison of flushing techniques

More details

Increased clamp speed and cycle time with reduced mold change downtime for a plastic manufacturer

More details

Reducing unscheduled maintenance and stoppages at an Industrial Gas plant

More details

Prevention of massive oil disposal at a Nuclear Power Plant

More details

Increased productivity and reduced man-hours for a Global Plastic Manufacturer

More details

Restoring System performance for an Aerospace Component Manufacturer

More details

Eliminating Lubrication related failures at an Industrial Gases Manufacturer

More details