We’ve helped customers globally to increase their uptime, convert their operations into Fill4Life™ systems and save them money in our documented case studies.

Case Studies to Repair your Oil, Boost your Uptime and ROI

Explore case studies

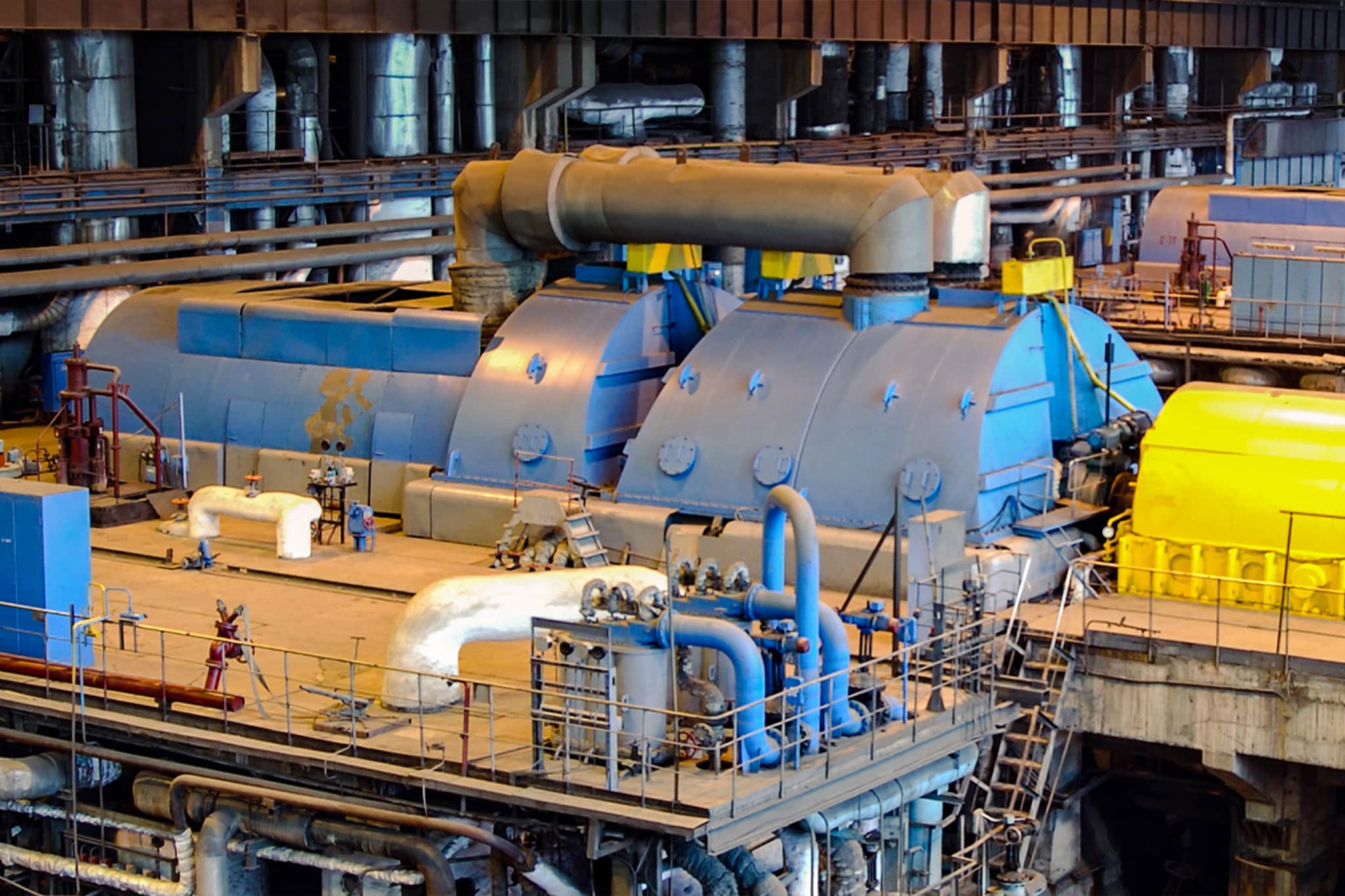

Mobil™ Solvancer® Helps New Jersey Power Plant Save $104K

More details

Optimizing Maintenance Costs and More at a German Power Plant

More details

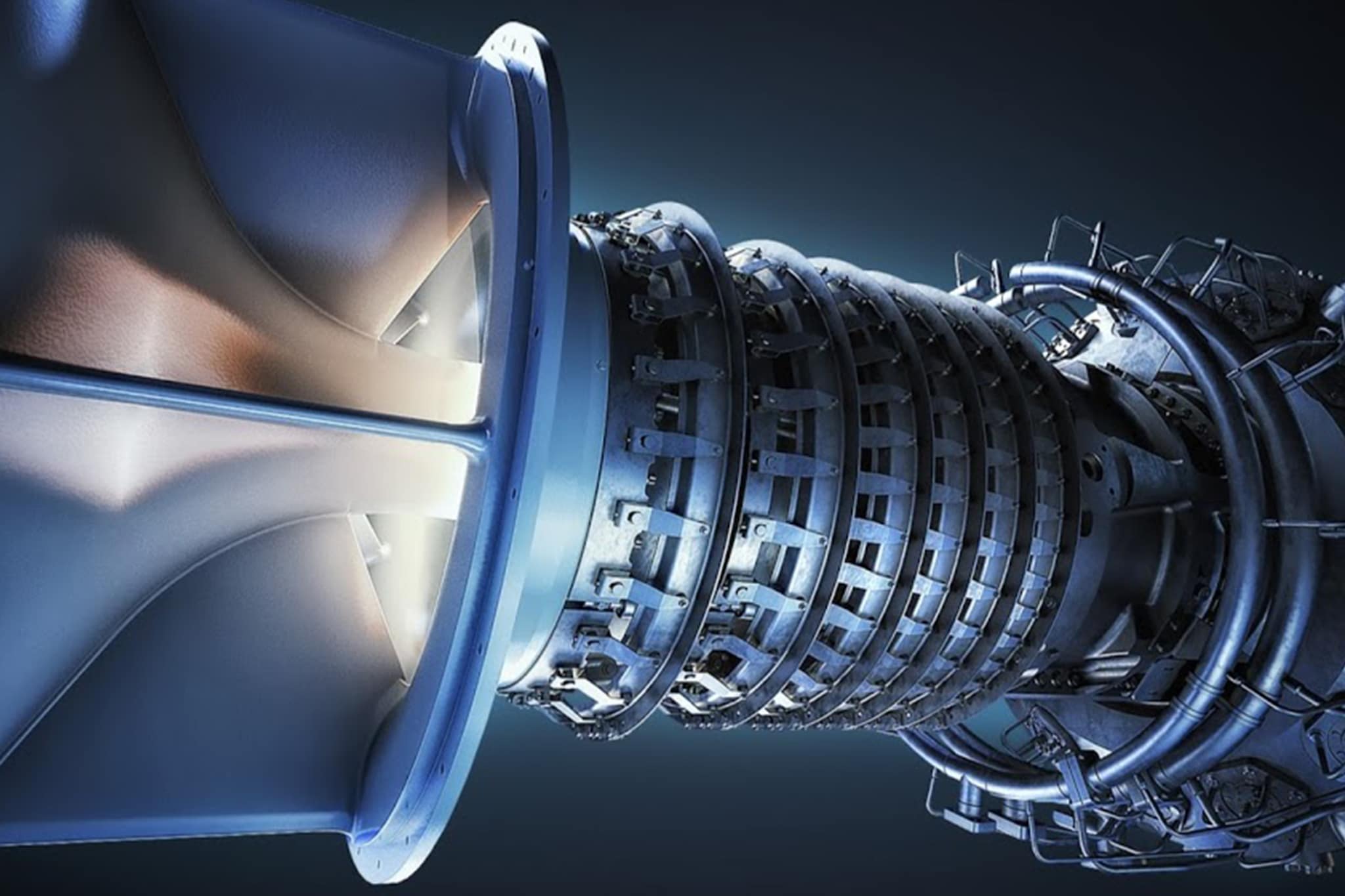

University Campus extends turbine oil life x5 times

More details

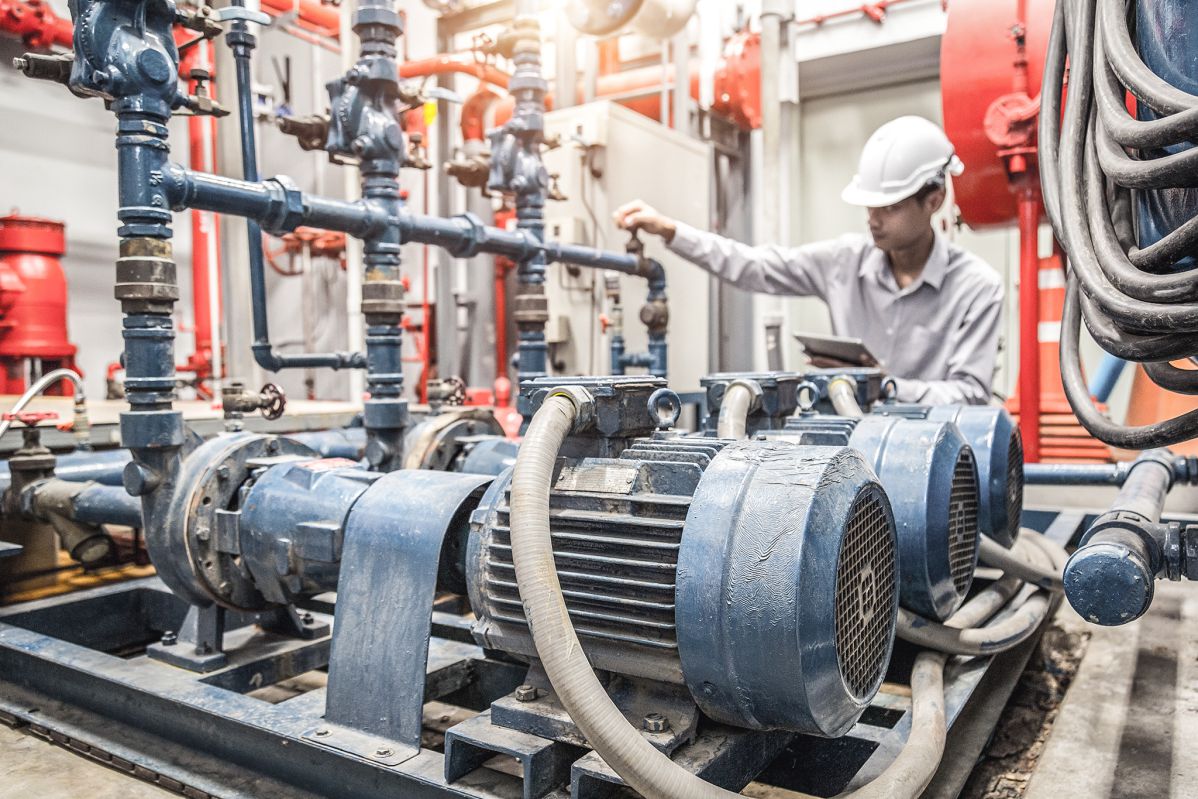

Side by Side comparison of flushing techniques

More details

Prevention of massive oil disposal at a Nuclear Power Plant

More details