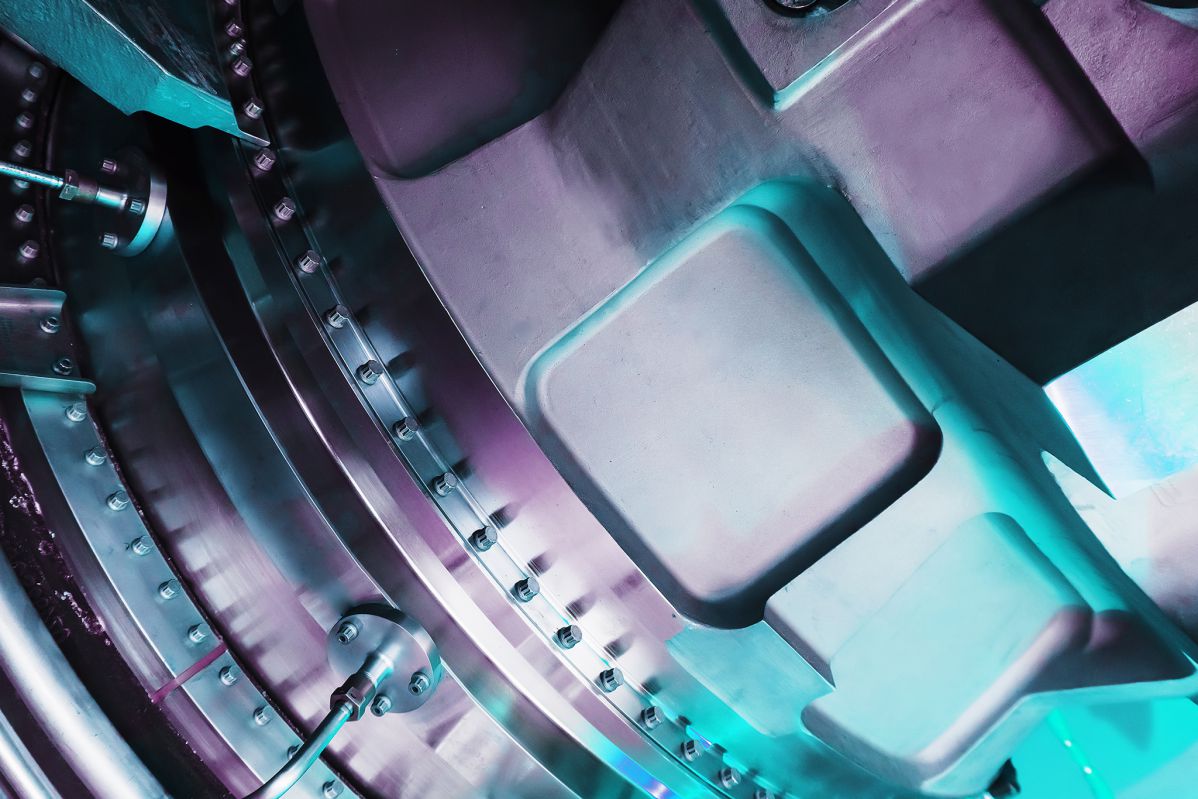

Solar Turbine

Problem

At a University campus in the USA, a Taurus 60 and a Taurus 70 packages were responsible for providing central power to the entire campus. Both turbines experienced rapid fluid degradation, evidenced by critical MPC values, deposits in the system, elevated bearing temperatures, premature filter changes and short oil life. The oil was changed every two years in each turbine. DECON was added prior to their next oil change to decontaminate the system, avoiding having to do a flush. This saved significant downtime during their outage. The University then upgraded their lubricant to Infinity TO. After two years of service, the antioxidants are healthy and the varnish potential (MPC) is in the single digits.

Solution

Fluitec’s Infinity TO™ replaced both in-service oils

Results

- Expect 10+ year life in performance

- System is now contaminant and deposit free

- Reduced downtime due to blocked filters and system deposits

- Normal bearing temperatures

- Avoidance of unplanned outage typically costing $1M+