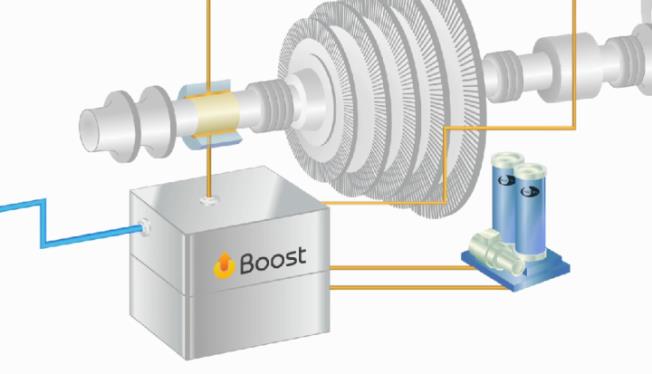

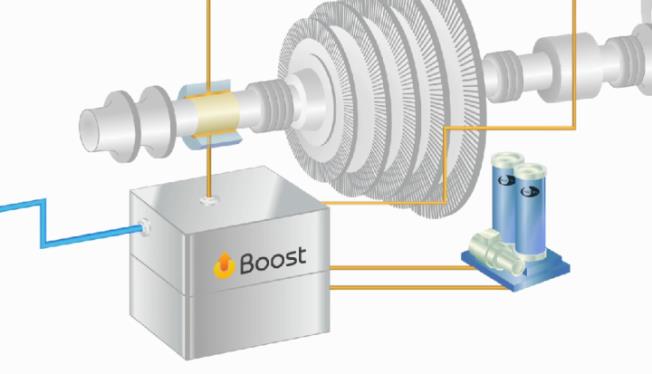

While Boost AO and the VITA Electrophysical Separation ProcessTM (ESP) deliver significant advantages on their own, together they create a true Fill4LifeTM system that replaces antioxidants and removes oil degradation by-products for a cleaner, greener operation.

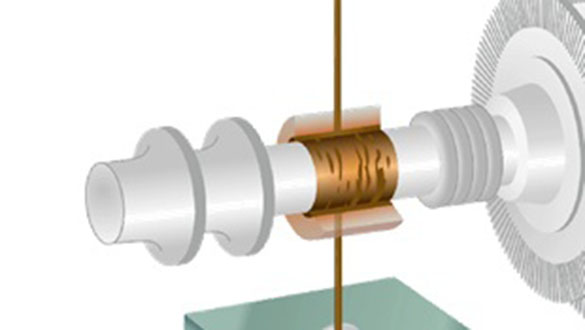

Depleted antioxidants create varnish causing byproducts in the oil

Working Together for Better Results

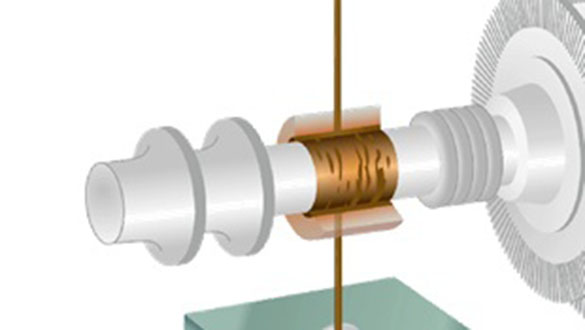

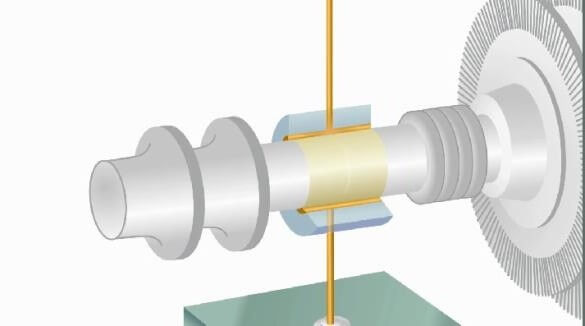

The thermal and oxidative stresses cause two problems: they deplete the sacrificial antioxidants in oil and create varnish, a detrimental by-product. As a turbine oil treatment, Boost AO replenishes depleted antioxidants but still leaves the problem of varnish.

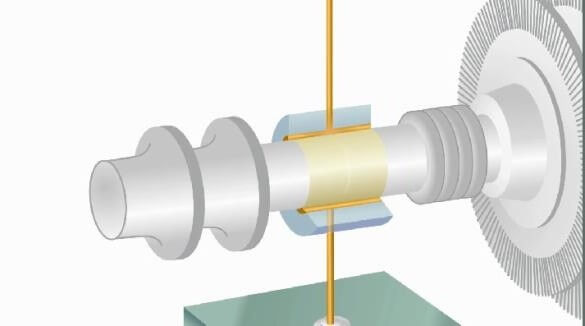

Fluitec developed the VITA ESP. Through a process called chemisorption, ESP technology removes suspended or dissolved oil degradation products without disturbing the fluid’s additive system. For best results, the ESP media should be tailored to each application and selected based on oil type and condition.

ESP removes the Varnish from the oil and Boost AO replenishes antioxidants

System cleanliness and antioxidants are restored