Plastic Manufacturer

Problem

A plastic manufacturer experienced slower clamp speeds and cycle time in their injection molding machines leading to lower productivity. Furthermore, the maintenance time required to change their molds was hampered by sticky, varnished-up components.

Solution

Fluitec’s DECON™ Fluid Enhancement Solution utilizing a patent-pending lubricant varnish and deposit mitigation technology, Solvancer® has maintained high levels of success enabling increased productivity for injection molding plants.

Results

DECON was shown to not only eliminate varnish formation in this thermally-stressed gearbox application but also allowed the plant to extend their drain interval from 3-months to 12-months.

- Increased clamp speed

- Increased cycle time

- Reduced scrap rate

- 66% reduction of downtime during mold change-over

Reduced Mold-Change Downtime by 66%

Deeper Dive

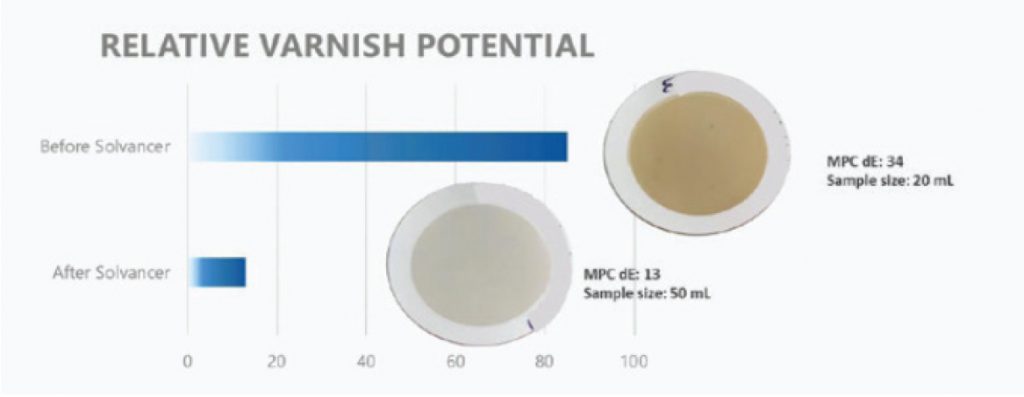

A plastic manufacturer had a problematic machine where they wished to try DECON with Solvancer. A normal MPC test could not be performed on this fluid, as the 0. 45μm membrane patch was blocked after only 20 out of 50mls of oil made it through the patch. The color of the patch was measured at a dE of 34.

DECON was added to this plastic injection molding machine. Over the course of a day, the varnish potential dropped considerably. During the MPC test, all 50mls of oil sample made it through the patch and the resulting color was a dE of 13. To provide a relative comparison of the before and after tests, the dE value of the before sample was adjusted to reflect the differences in filtrate volume.

Figure 1: Impact of DECON with Solvancer in hydraulic oil from a plastic injection molding machine. The initial sample had an MPC value of 24, however only 20 out of 50ml could be filtered through the patch. After treatment, all 50 mLs of hydraulic oil could be filtered.

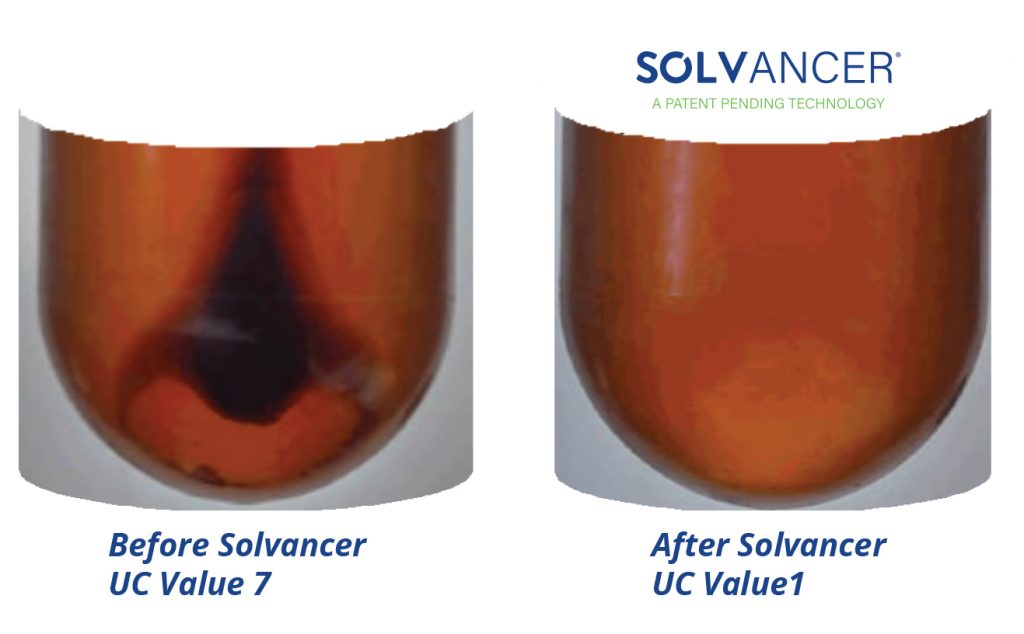

Another varnish potential test that is often used on in-service oils is the Ultra-Centrifuge (UC) test. This method extracts soluble and insoluble material from the oil by spinning the fluid in a test tube at 17,000rpm. A visual assessment is made on the separated deposits and the fluid is given a rating on a scale between 1 and 8. The addition of DECON to the in-service hydraulic oil showed a significant improvement in the UC test.

Figure 2: UC Values before and after the addition of Solvancer.

After treating the in-service hydraulic oil with DECON, the plant noticed an immediate improvement in clamp speed and cycle time. Furthermore, significantly less time was required during their next shutdown to facilitate a mold change-over.