Extending oil life

Problem

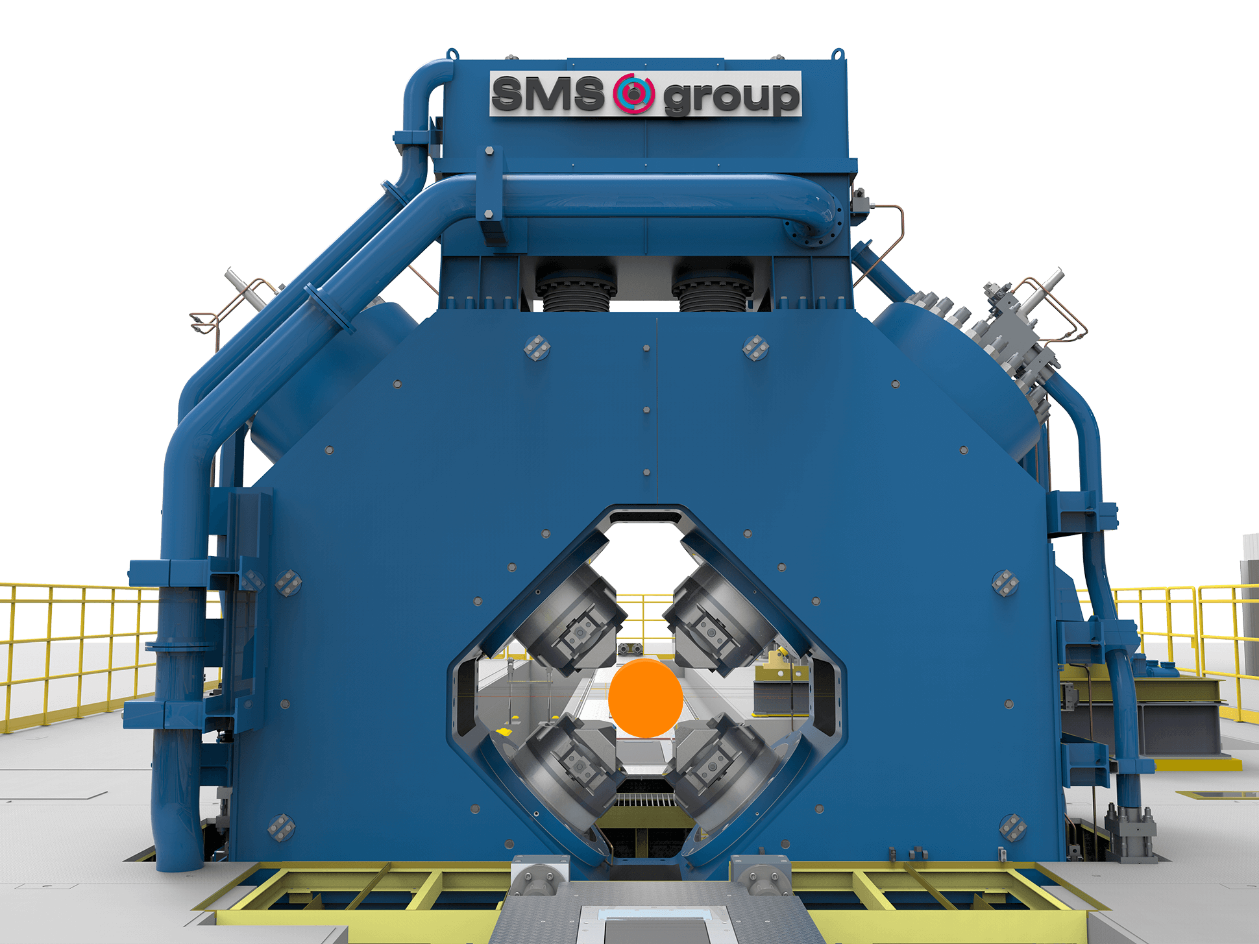

A leading Aerospace Component Manufacturer noticed a decrease in ram speed with their hydraulic radial forging press

creating inconsistent system performance, risking product quality.

Solution

Fluitec’s DECON™ Fluid Enhancement Solution utilizing a patent-pending lubricant varnish and deposit mitigation technology, Solvancer™ was added to the in-service hydraulic oil and circulated throughout all four reservoirs.

Results

- Within a week, the varnish potential was lowered

- Heavily varnished components began to clean

- Ram speeds were restored and valves no longer stuck

Within a week, the varnish potential was significantly lowered and DECON had restored system performance while simultaneously cleaning system internals.

Deeper Dive

The Aerospace Component Manufacturer’s hydraulic radial forging press comprises 4 x 12,000 gallon reservoirs with hydraulic fluid from each reservoir powering one of four cylinders. Upon having performance-related issues, an inspection later revealed a manifold riddled with varnish deposits. Deposits were also found in pumps, valves and system internals. Further oil analysis revealed high varnish potential. Three-percent DECON was added to the in-service hydraulic oil and circulated throughout all four reservoirs.

Within a week, the varnish potential was significantly lowered and DECON had restored system performance while simultaneously cleaning system internals. DECON is also currently preventing the formation of additional deposits. The manufacturer is continuing to monitor the fluid on a monthly basis, including the MPC (Membrane Patch Colorimetry) test. The manufacturer will add approximately 3% DECON along with new oil whenever the system needs to be topped-up to maintain superior performance.