Extending oil life and increasing bottom line

Problem

One of the United State’s largest public power utilities provides reliable, reasonably priced electricity and water to more than 2 million people in Central Arizona. Plant managers were concerned with the presence of oil degradation so early on in the life of the combined-cycle power plant. Oil analysis indicated a high MPC (Membrane Patch Colorimeter) varnish potential in oil as well as antioxidant depletion.

Solution

Fluitec’s Boost AO™ Fluid Enhancement Solution for risk-free antioxidant rebalancing.

Results

- Replenished depleted antioxidants

- Well over 150% of the industry standard for oil life

- Saved over 50,000 gallons (190k L) of oil

- Extended the life oil

- Increased plant efficiency and lowered CO2 emissions

“When you consider we would have changed the oil twice by now and even conservatively averaging lube oil related trips and fail-to- starts, the savings are in the millions.”

– Mark Joy, Operations & Maintenance Supervisor

Deeper Dive

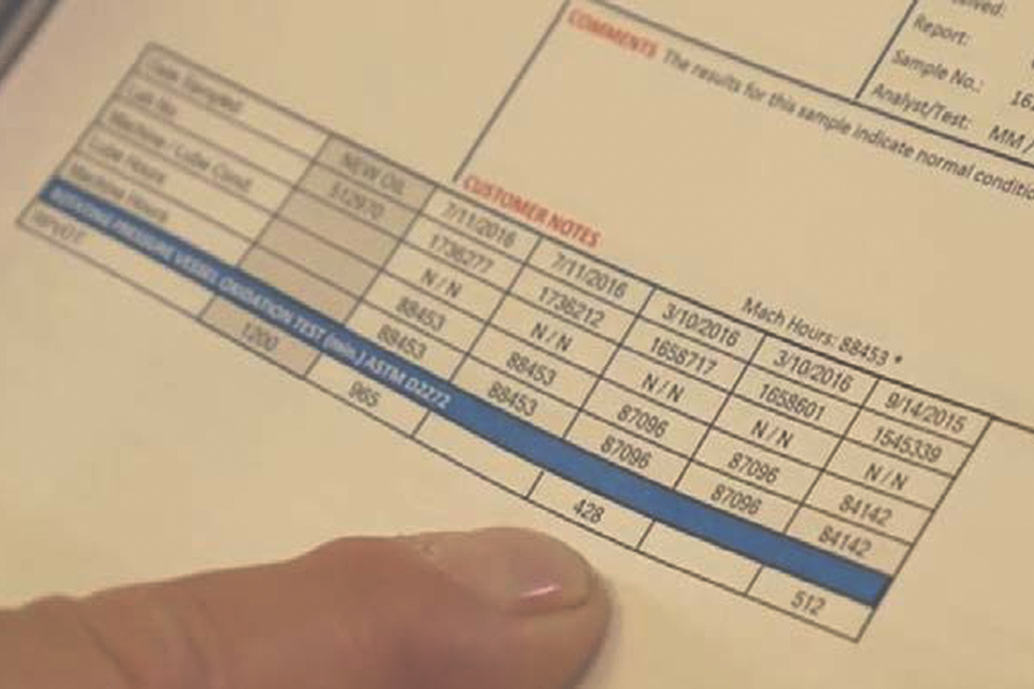

The Operations and Maintenance Team believed that oil is the lifeblood of any rotating equipment. There are many lube oil degradation problems that are widely acknowledged in the power generation industry, including varnish, sticking valves and elevated bearing temperatures. Oil analysis indicated a high MPC (Membrane Patch Colorimeter) varnish potential in their oil and antioxidant depletion (RPVOT and RULER™ tests).

Mark Joy, Operations & Maintenance Supervisor, was concerned with the presence of oil degradation so early on in the life of his combined-cycle power plant.

From Mark’s experience he knew he had to act fast or he would start experiencing efficiency issues that could lose some serious revenue. Even GE says the average power plant will have 8 fail-to-starts per year, two of which being lube oil related; and a lube related trip every two years. The plant wanted to avoid trips and downtime, save on expensive oil change and flushes and do so in an environmentally positive way.

Mark attended a Lubrication Academy hosted by Fluitec and learned why he was seeing signs of oil degradation. He turned to Fluitec for the solution to remove and control varnish contamination and then, once qualified, used Boost AO to replenish the depleted antioxidants. This was over a decade ago and he has never changed the oil. He uses routine oil analysis to monitor his oil’s condition. His last result shows the oil is as good as (even better than) new oil because of his use of Boost AO.

To date SRP is well over 150% of the industry standard for oil life due to Boost AO. Their initial goal is of 100,000 operational hours (≈13 years) of oil life is soon to be reached and they are looking to double that goal to 200,000 hours with no oil change.

“When you consider we would have changed the oil twice by now and even conservatively averaging lube oil related trips and fail-to- starts, the savings are in the millions.”

Even beyond the monetary savings there’s a serious environmental impact.