Problem

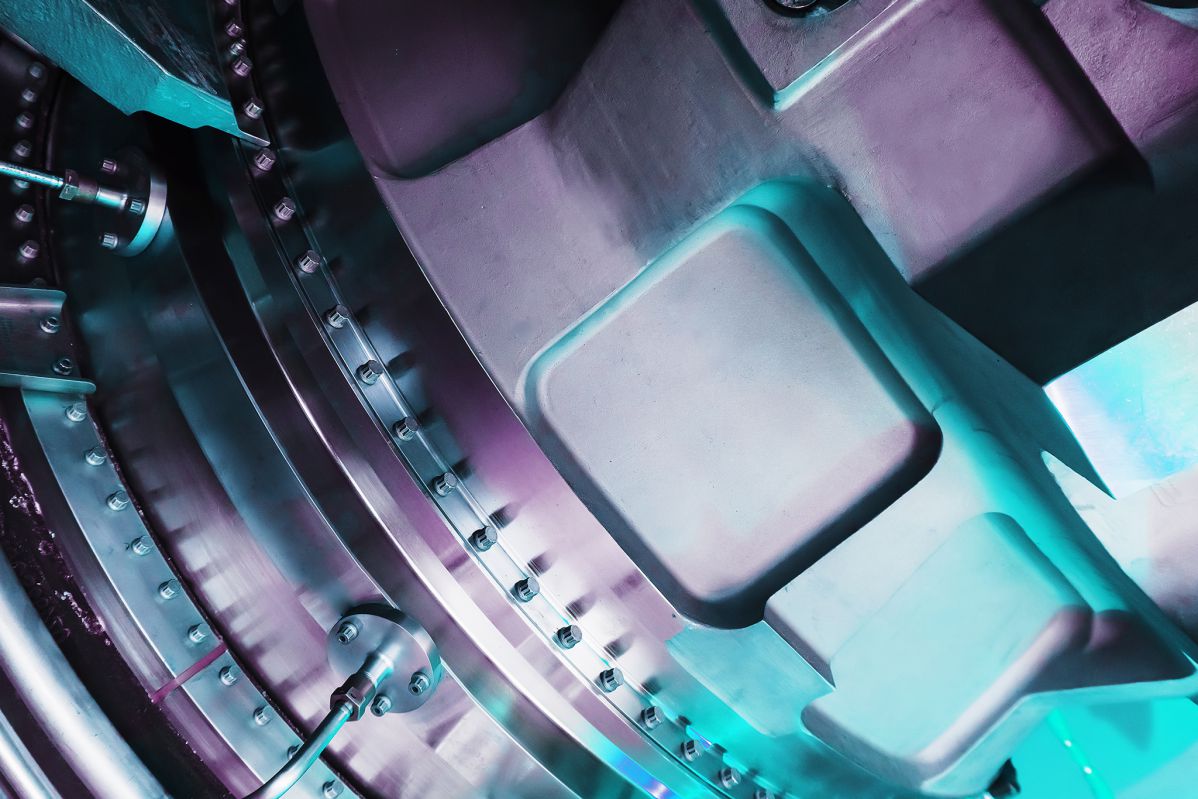

In a major German power plant, signs of potential varnish in a turbine manifested as orange-brown deposits and increased foam formation. Heightened bearing temperatures were also noted in the pinion bearing. Despite MPC levels staying within the normal range, RULER® values showed a substantial decline in antioxidants, reaching threshold values alongside other critical indicators. The turbine oil was thus considered to have reached the termination point of its service life.

Solution

Introducing DECON AO™ at a 3% treat rate dissolved system varnish, replenishing critical antioxidants and eliminating the need for any necessary action for at least the next scheduled overhaul in five years. The Fluitec ESP VITA II™ system was also employed for oil cleanup, preceding the overhaul.

Results

Upon the addition of DECON AO, varnish deposits were effectively eradicated from the system. This intervention led to a substantial reduction in MPC levels, accompanied by significant elevations in RPVOT and RULER values. Remarkably, equipment shutdown for a flush was obviated.