Natural Gas Supplier

Problem

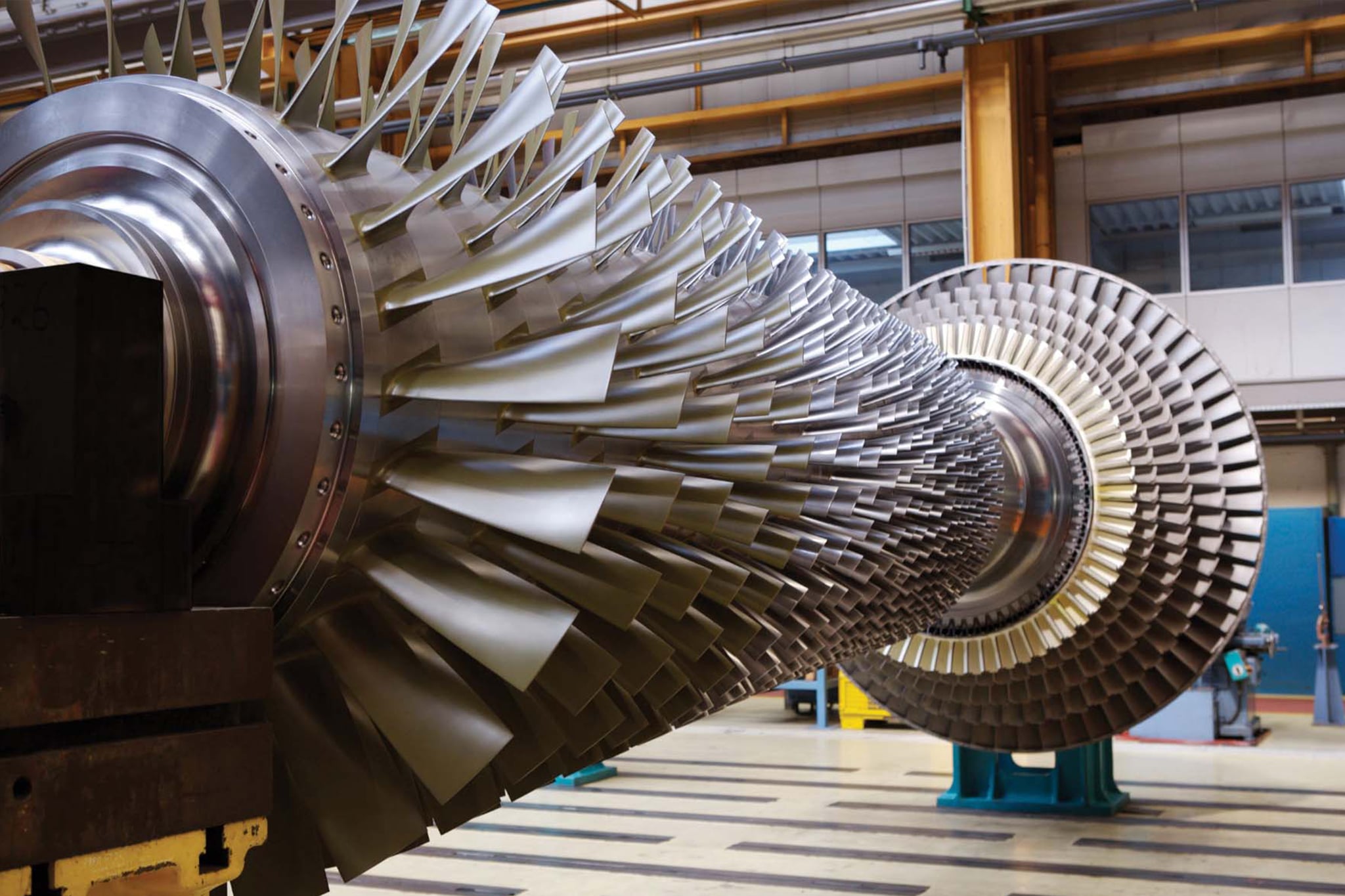

A major natural gas supplier with various locations across the US wanted to change the oil in 10 of their Solar Turbine gas packages. However, in each of these systems, the oil was badly degraded with low antioxidant levels and elevated varnish potentials. If a new batch of oil was simply placed in the system, all of the varnish deposits would still exist and cause accelerated degradation to the new oil. This could lead to unexpected downtime and the use of mechanical flushing which would require the systems to be taken offline.

Solution

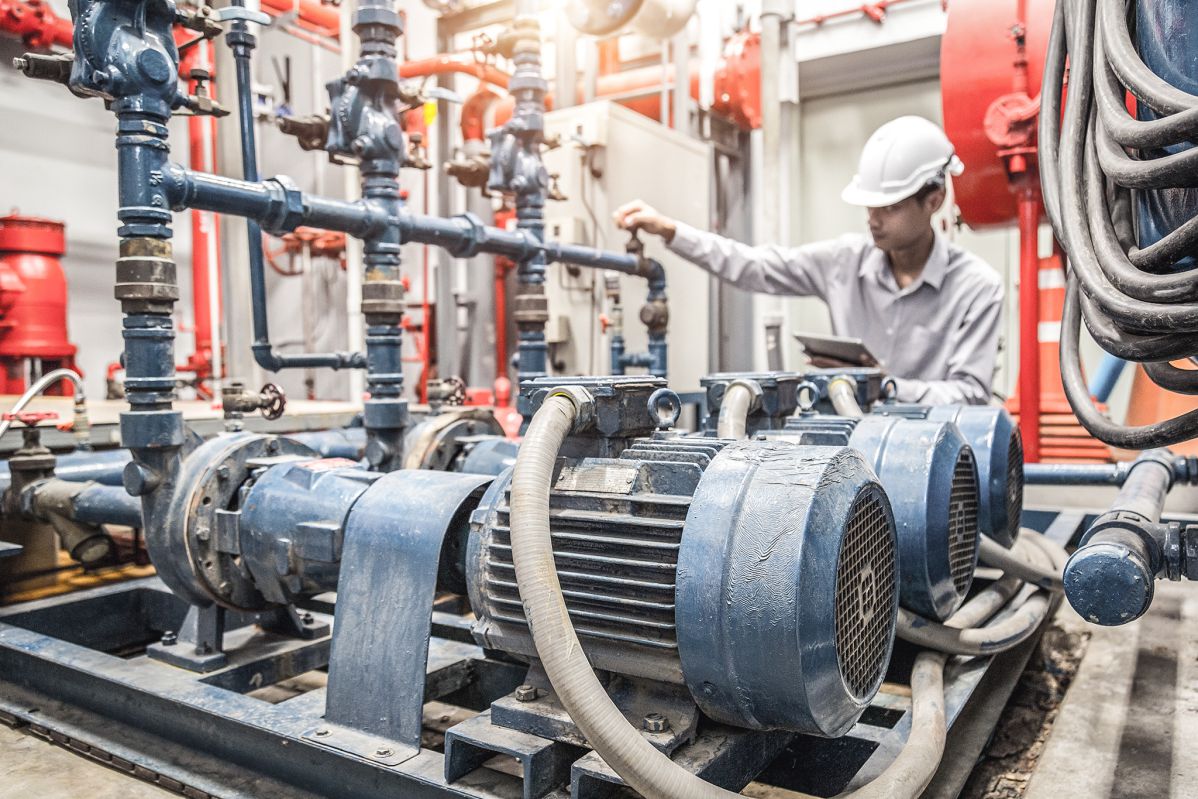

Analyses were conducted for each unit and individual treat rates of Fluitec’s Boost VR were recommended. Due to the nature of degradation experienced by some units, it was necessary to install Fluitec’s ESP unit to assist in the cleaning of the oil.

Results

- Approximately 1-3 months before the scheduled change out of oil, Boost VR was added to the system at the prescribed rates and the ESP units were attached accordingly.

$128,000 in Cost Savings Annually

Other Projects

Extending the oil life of a gas compressor at an Air Separation Plant

ESP and Boost VR / USA

More details