Problem

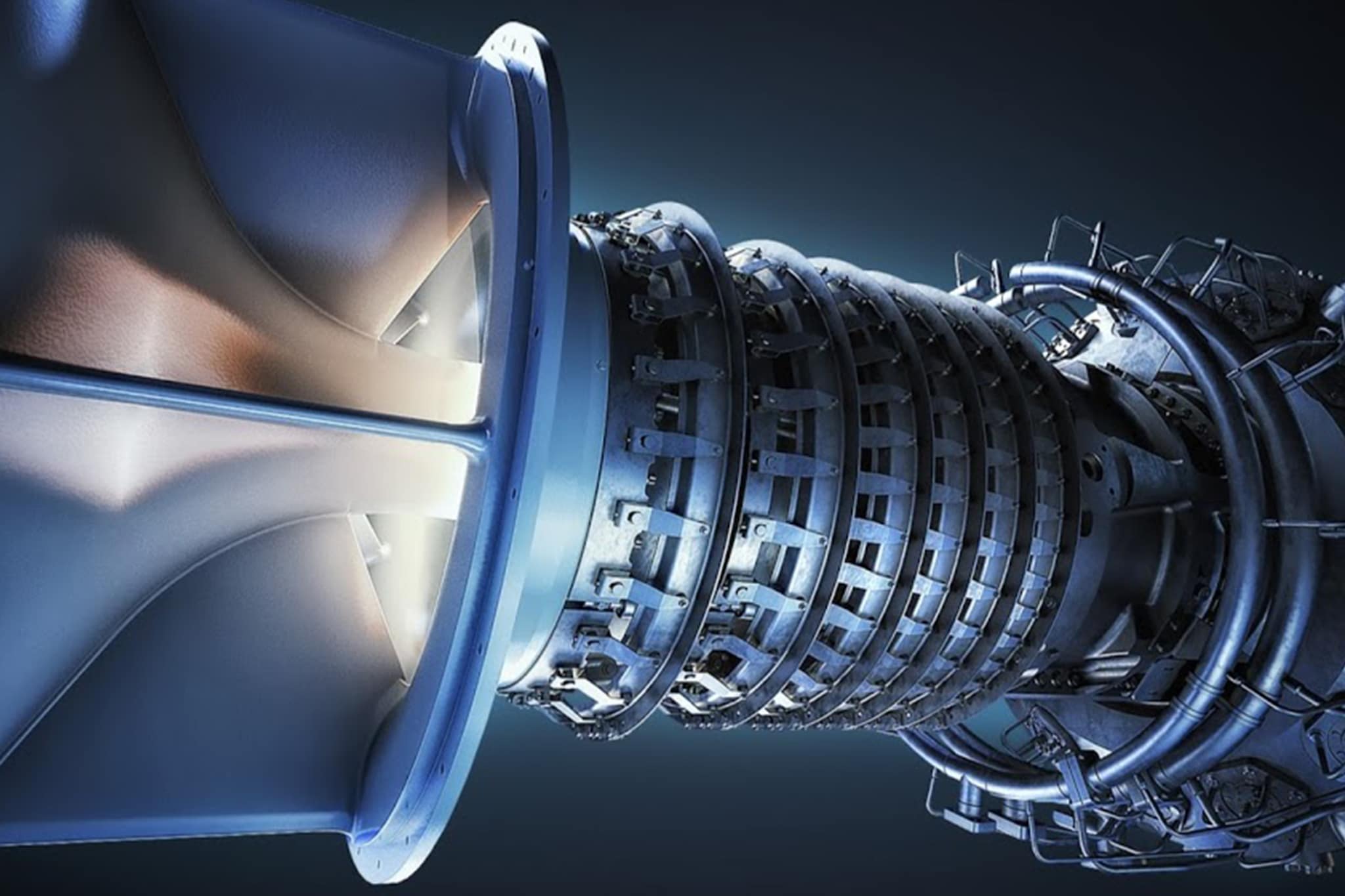

Elevated bearing temperatures on a turbine driven Air compressor in a Petrochemical Plant in China posed the risk of an unplanned outage. Increased levels of varnish deposits were visibly present on the thrust bearings and gear teeth. The MPC values were in the Critical range and the oil was failing.

Solution

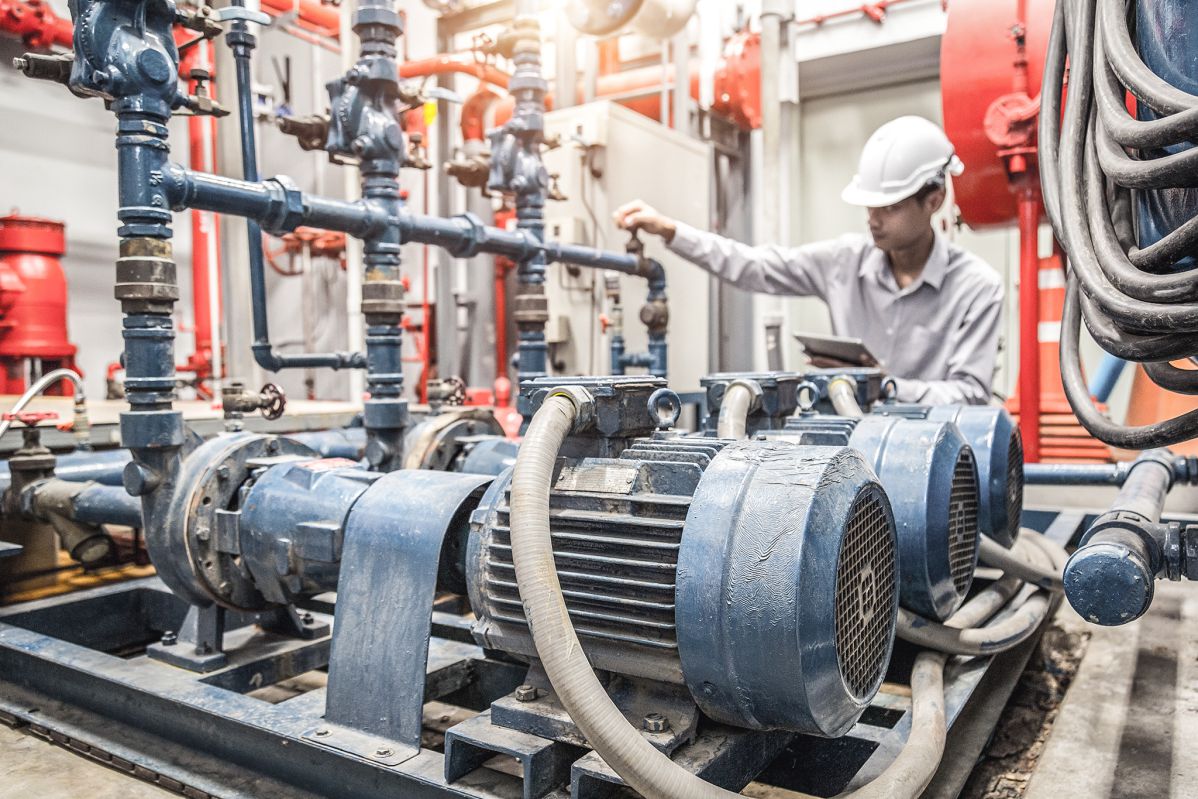

Fluitec’s ESP VITA™ unit was installed to clean up the deposits formed which would lead to a reduction in bearing temperatures.

Results

- Drop in MPC to normal range within 80 days. MPC levels maintained in the normal range for four years with the ESP system.

- Bearing temperatures maintained below the warning limit allowing the plant to operate without fear of bearing damage.

- Avoidance of unplanned outage typically costing $1M+

$1,000,000+ in Cost Savings