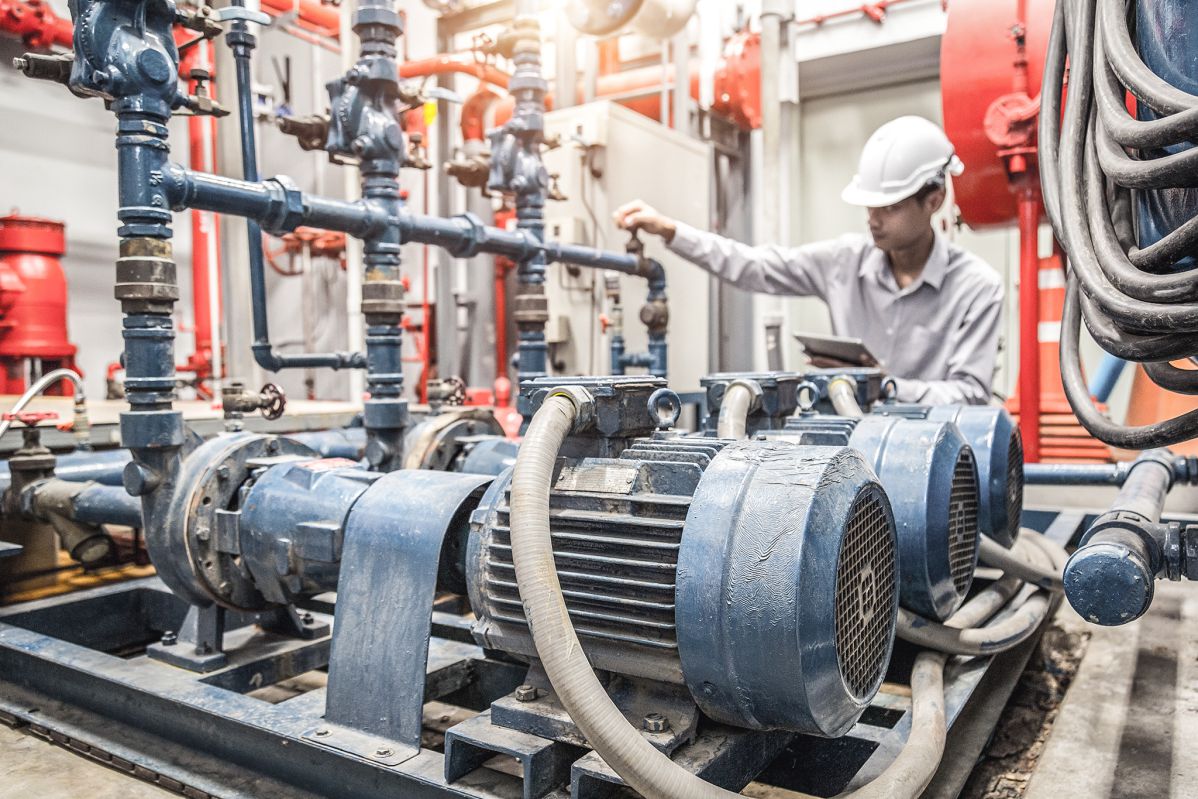

Petrochemical Plant

Problem

In a petrochemical plant in China, visual varnish deposits were reported on the thrust bearings and gear system of an air compressor which was driven by a turbine. High bearing temperatures were also noticed on this air compressor. The MPC levels were outside of the normal range at 40 indicating that a shutdown would be imminent.

Solution

Fluitec’s ESP unit was installed on site

Results

- MPC values normalized and after the first two months the values were within the range of 15.

- Within two years of the ESP unit being installed, the thrust bearing pads appeared clean and were free of any deposits.

- Bearing temperatures have also decreased drastically

$228,000 in Cost Savings

Other Projects

Extending the oil life of a gas compressor at an Air Separation Plant

ESP and Boost VR / USA

More details