Major Offshore Oil and Gas Operator

Problem

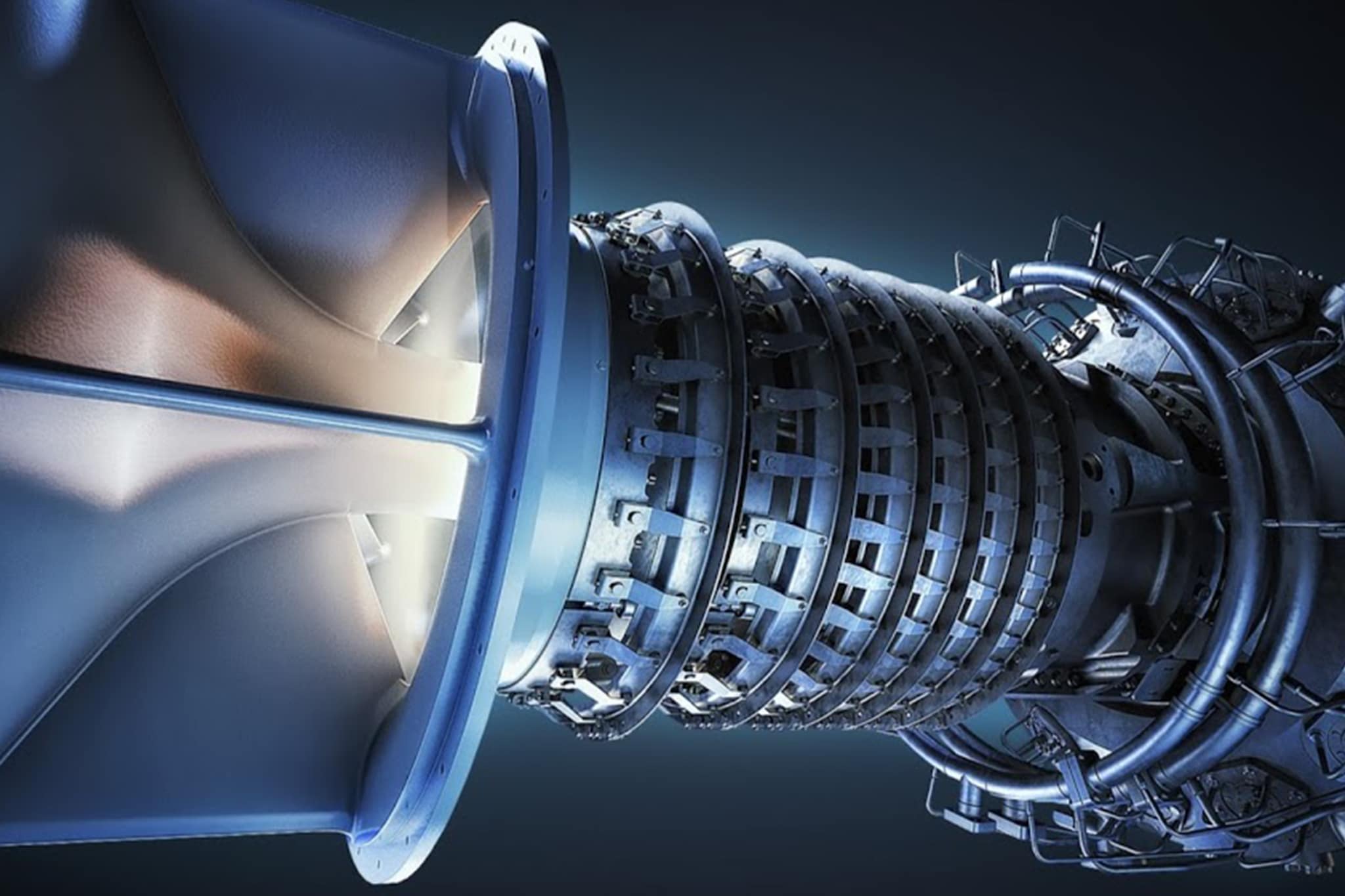

A major offshore oil and gas company with a fleet of 27 Solar Turbines began noticing high temperature spikes and increased vibration alarms for most of the equipment. Upon further investigation, they found the presence of deposits in most of the equipment. Most of the MPC levels were above 20 (the Critical range).

Solution

The Ocean Team Qatar, a Petrotec company, began monitoring the oil’s condition more closely to establish trends and identify the issues with each turbine.

For the turbines with no scheduled oil changes, Fluitec’s ESP unit was used to filter out most of the varnish deposits. Afterwards, DECON was used to solubilize these deposits, prevent future formation and control the deposits. The ESP unit was then used again to filter out any additional deposits.

For the turbines which were scheduled for flushing and an oil change, Fluitec’s Boost VR+ was added to solubilize the deposits and the ESP unit was used to filter out any deposits.

Results

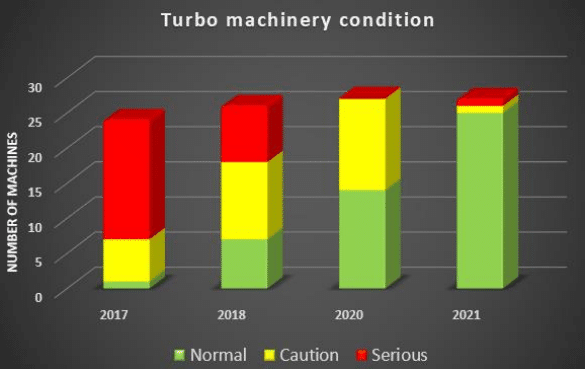

- From 2017 to 2021, the number of machines within the critical or serious modes have drastically reduced to one each as shown in the diagram below

- MPC values and vibration levels were reduced

- Oils remained within acceptable limits

- No unexpected shutdowns

- System is varnish free

$2M in Cost Savings

Other Projects

Extending the oil life of a gas compressor at an Air Separation Plant

ESP and Boost VR / USA

More details