Paper Production Plant

Problem

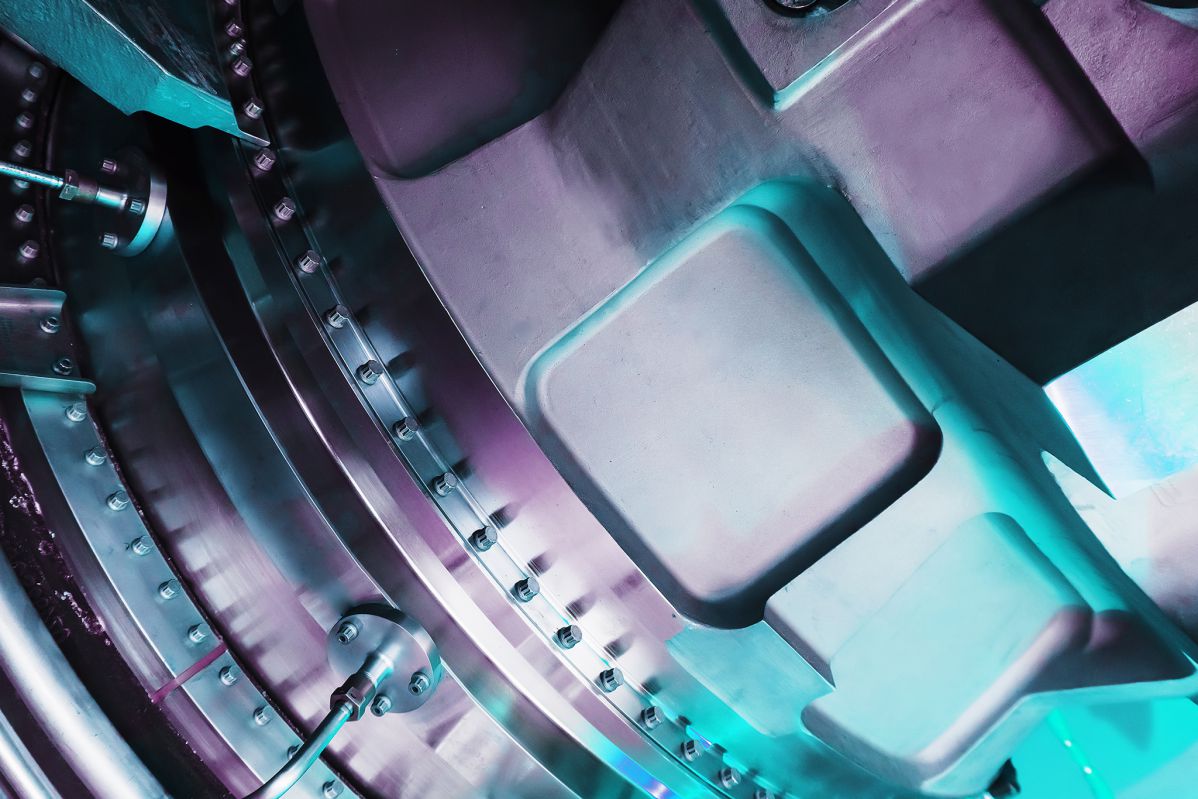

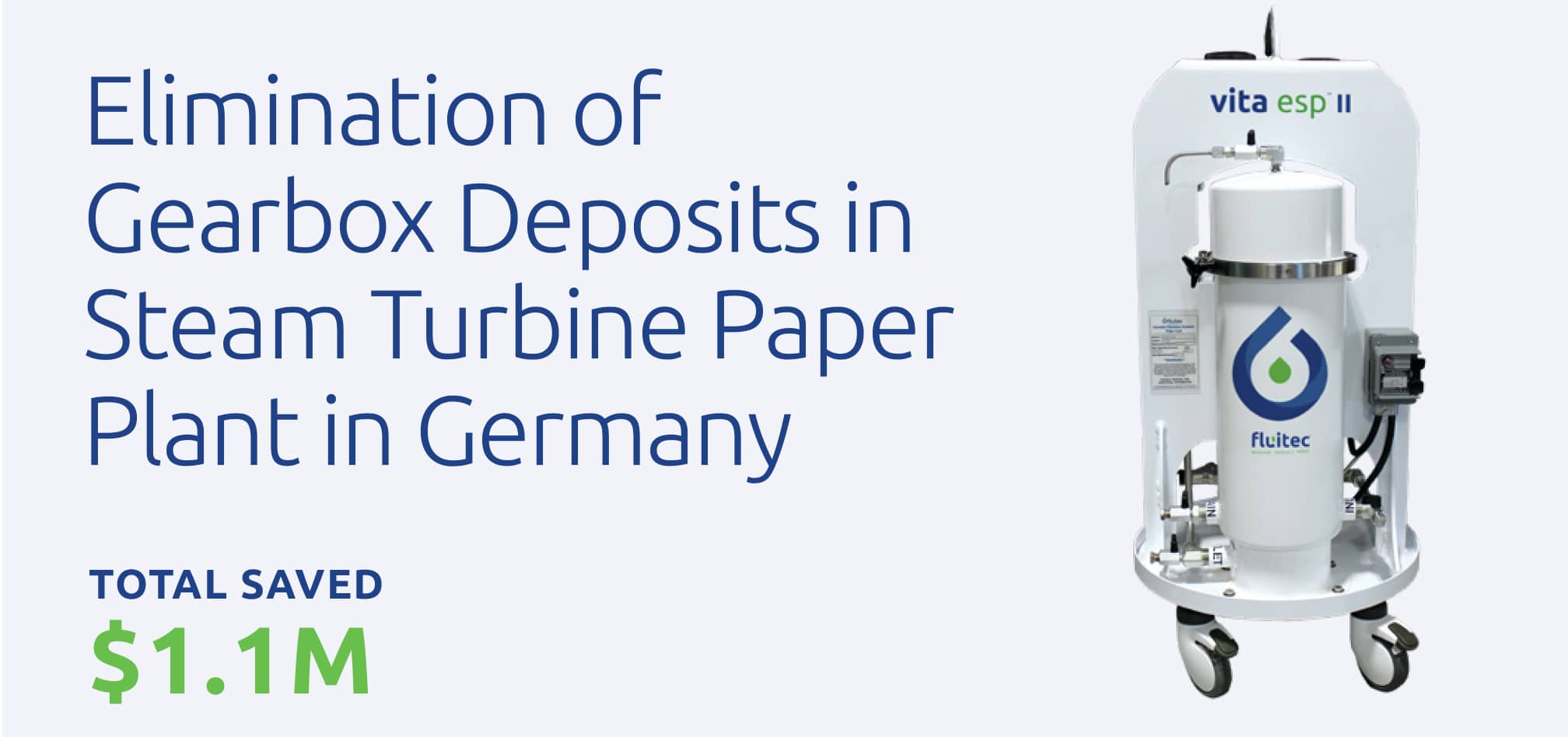

A steam turbine’s gearbox in a paper plant in Germany was experiencing an elevated amount of deposits in its radial bearings. These deposits caused an increase in the temperature of the radial bearings and threatened an unplanned shutdown of the paper plant which would cause a disruption in the production and delivery to its customers.

Solution

Fluitec’s Boost AO was added to the gearbox and the Legacy ESP unit was installed. Within one year of installation and multiple filter changes, the oil was cleaned up and the unit did not experience any downtime.

Results

- After the installation of the Legacy ESP & addition of Boost AO to the gearbox, there was a significant decrease in MPC levels from 38 to a maintained level of 12. The ISO cleanliness rate also greatly improved from 23/20/13 to 18/15/14 & 15/14/12. The system did not experience any unplanned downtime and the plant was able to successfully deliver its products to all of its customers.

$1.1M in Cost Savings

Other Projects

Extending the oil life of a gas compressor at an Air Separation Plant

ESP and Boost VR / USA

More details