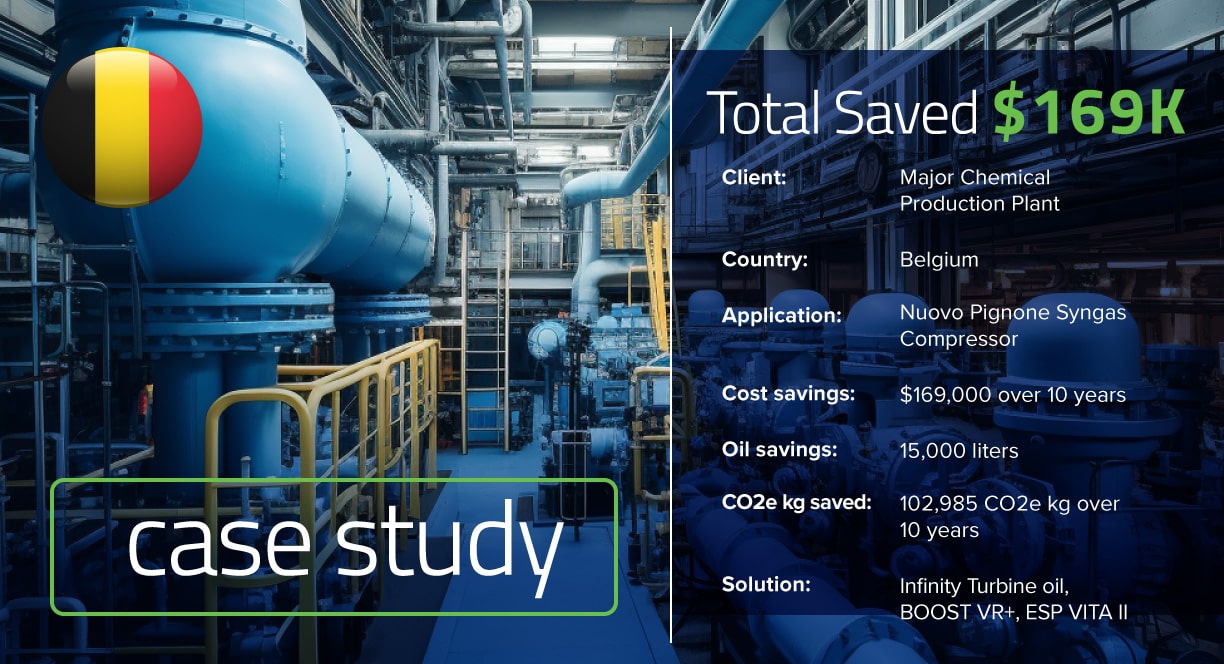

Problem

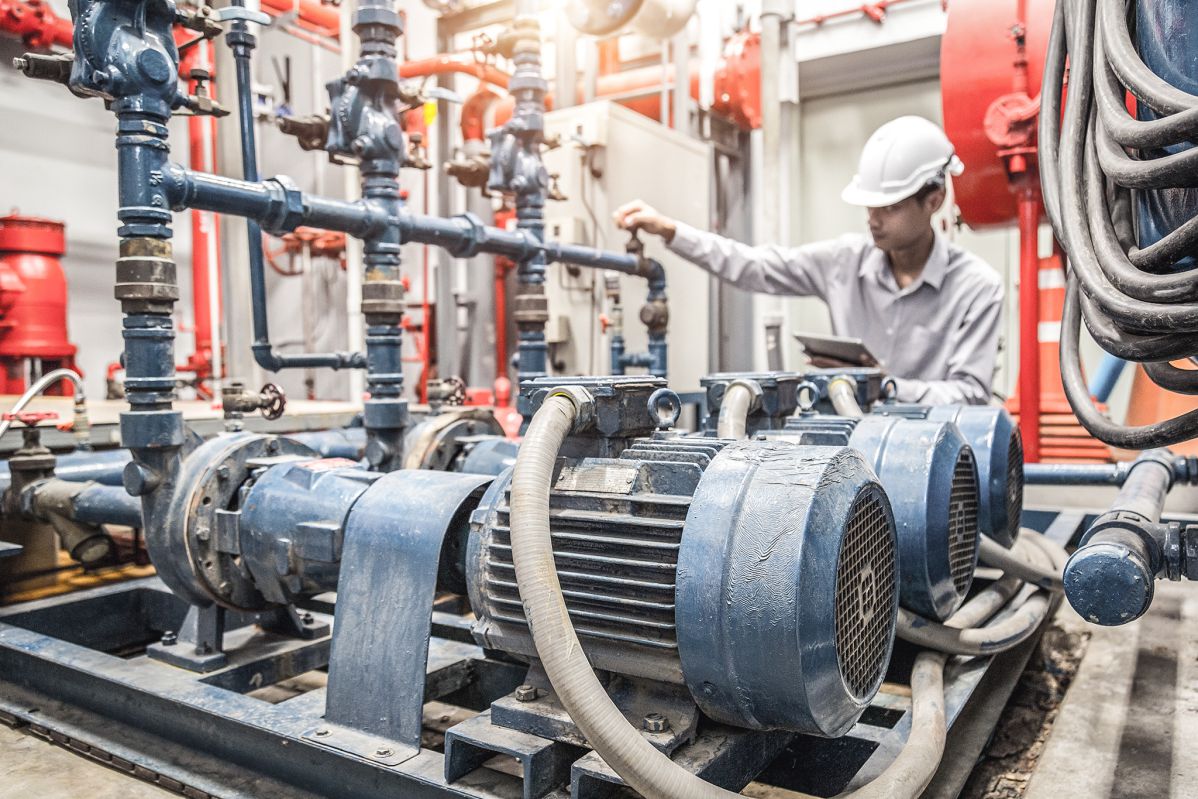

In a prominent chemical plant in Belgium experienced seal oil leakages and elevated bearing temperatures emerged, necessitating frequent replacements of seal oil. The escalating bearing temperatures posed a significant risk of triggering an unplanned shutdown.

Solution

Boost VR+™ was introduced into the system 4 months preceding an oil change, and in conjunction with the VITA ESP™ unit, systematically cleansed the system prior to the oil change, eliminating the necessity for a chemical flush. The new charge of Infinity™ Turbine Oil provides a 10-year deposit free guarantee and sets the plant up for a potentially Fill4Life Turbine oil.

Results

Following the introduction of Boost VR+ and installation of the VITA ESP II unit, deposits surrounding the seals were effectively eliminated. Over the past 2.5 years of employing Infinity Turbine Oil, MPC levels have consistently remained below 10. Notably, the seal oil flow has been normalized and temperatures reduced to below 40°C. In addition, visual inspection of the seal oil rings exhibits significant improvement in cleanliness. Finally, bearing temperatures have also stabilized without any saw-tooth peaks. This maintenance action has resulted in improved operational conditions and a longer estimated oil life. Several years from now, the plant will consider adding DECON AO rather than changing the oil.