Problem

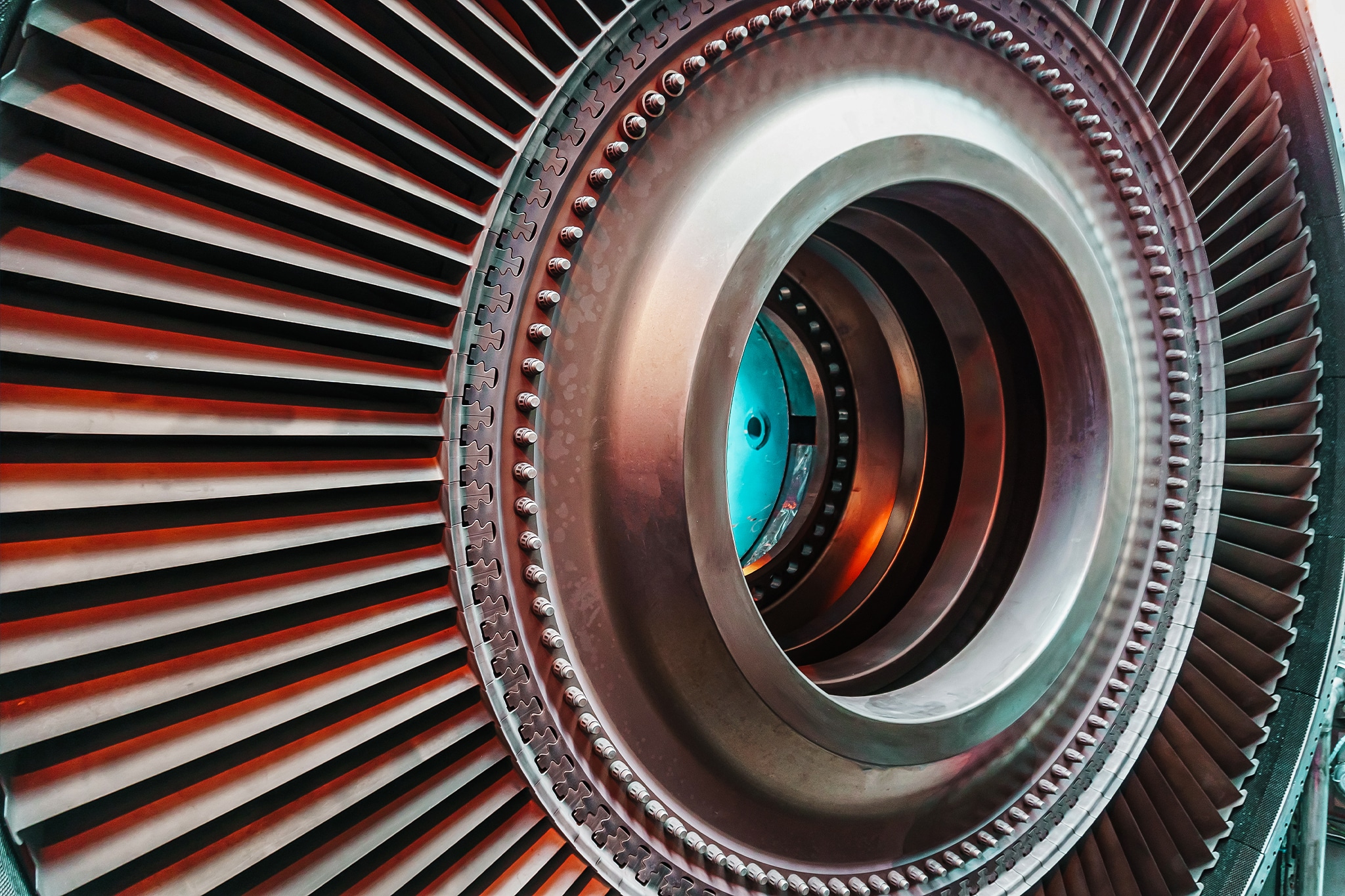

A prominent Oil and Gas corporation operating in Qatar observed an elevation in the thermal readings at the Non-Drive End (NDE) of their compressor unit. In response, they conducted a Membrane Patch Colorimetry (MPC) analysis, which yielded a result indicative of a low level of varnish potential. Despite the ostensibly minor MPC value, the escalating temperatures in the bearings posed a significant risk of leading to an unforeseen operational shutdown. The bearing temperature signature combined with oil analysis results suggest that Shear Stress is the primary mode of fluid degradation.

Solution

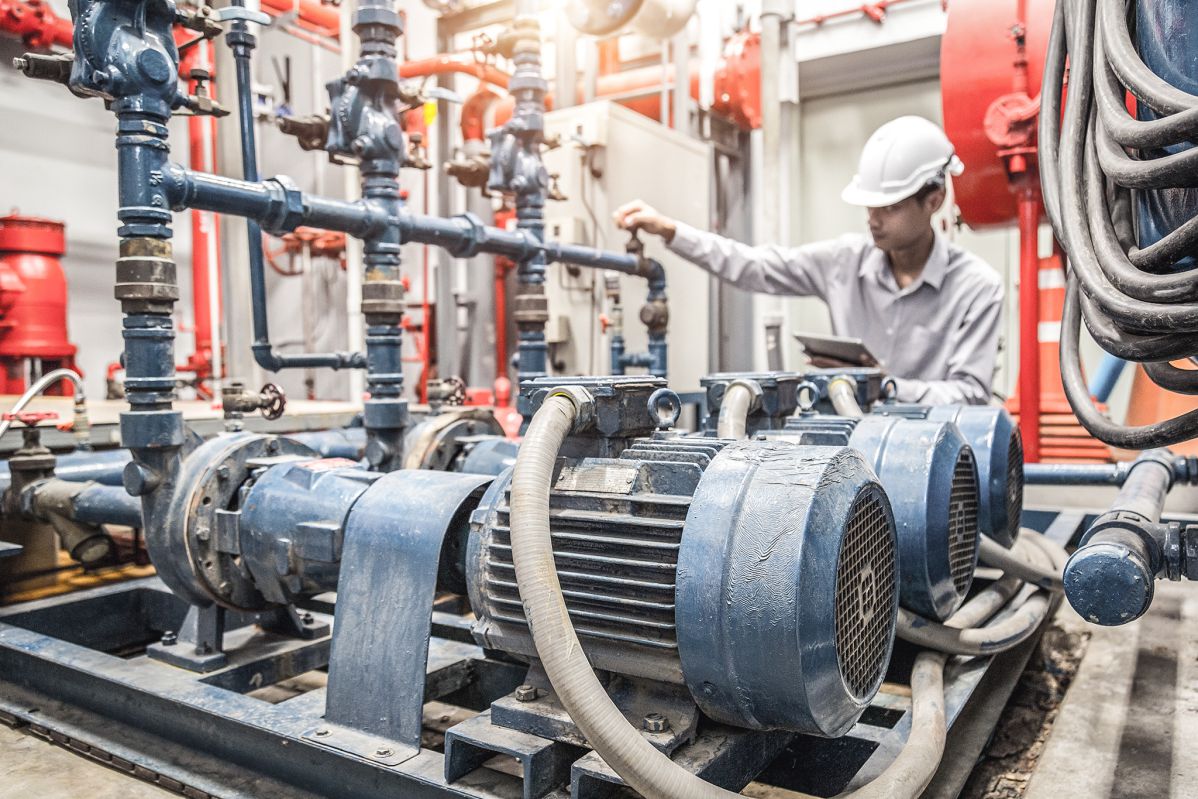

With the help of Petrotec, Fluitec’s ESP VITA™ unit was attached to the system to help remove the existing deposits. Over the period of one month, weekly samples were taken and the progress of deposit removal was tracked.

Results

Almost immediately, the bearing temperatures returned below the critical value and within two weeks, the MPC values were halved. Within one month, the ESP VITA III unit was taken offline and over the next couple of months, the bearing temperatures were maintained well below the critical value.