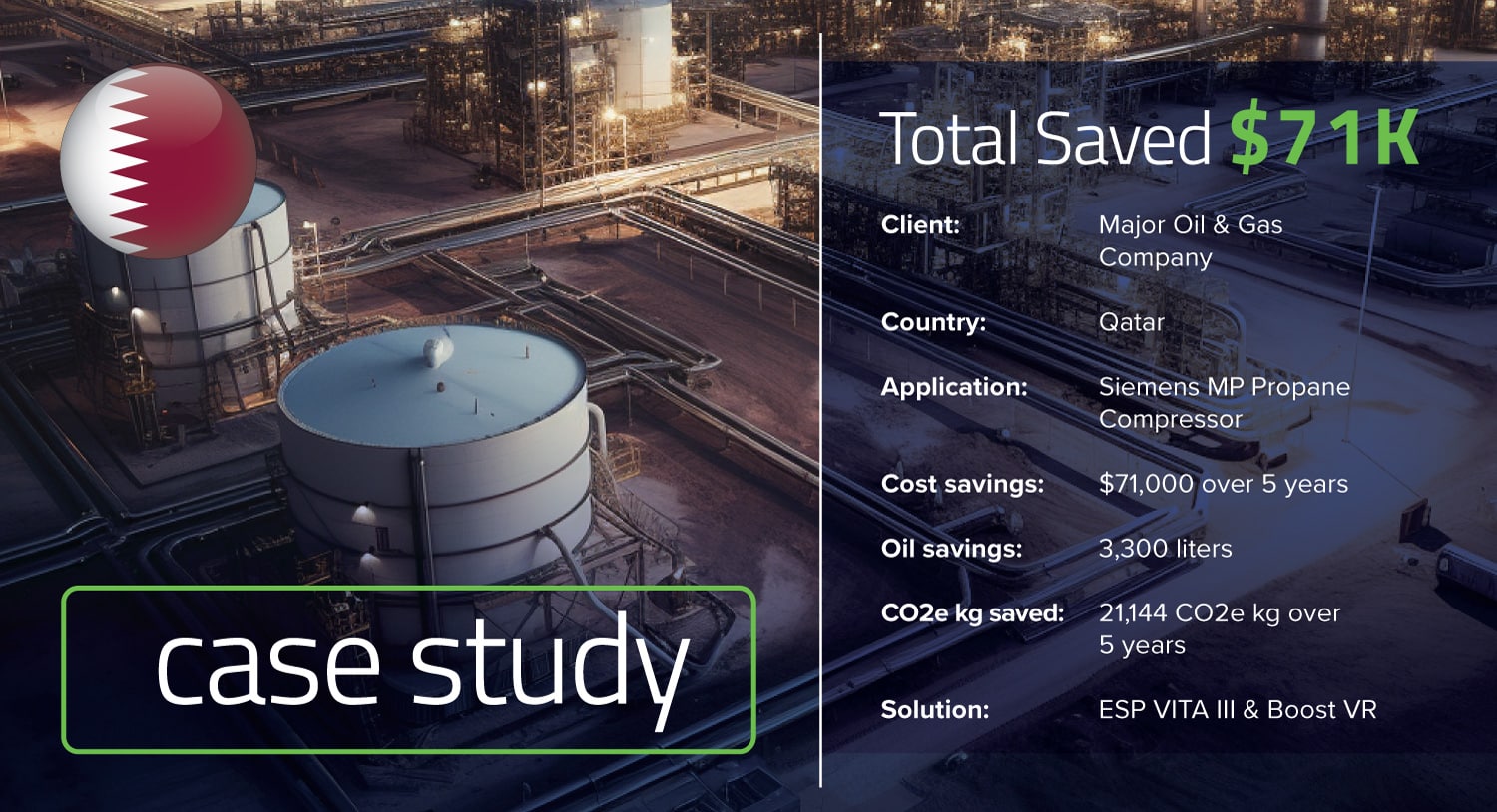

Problem

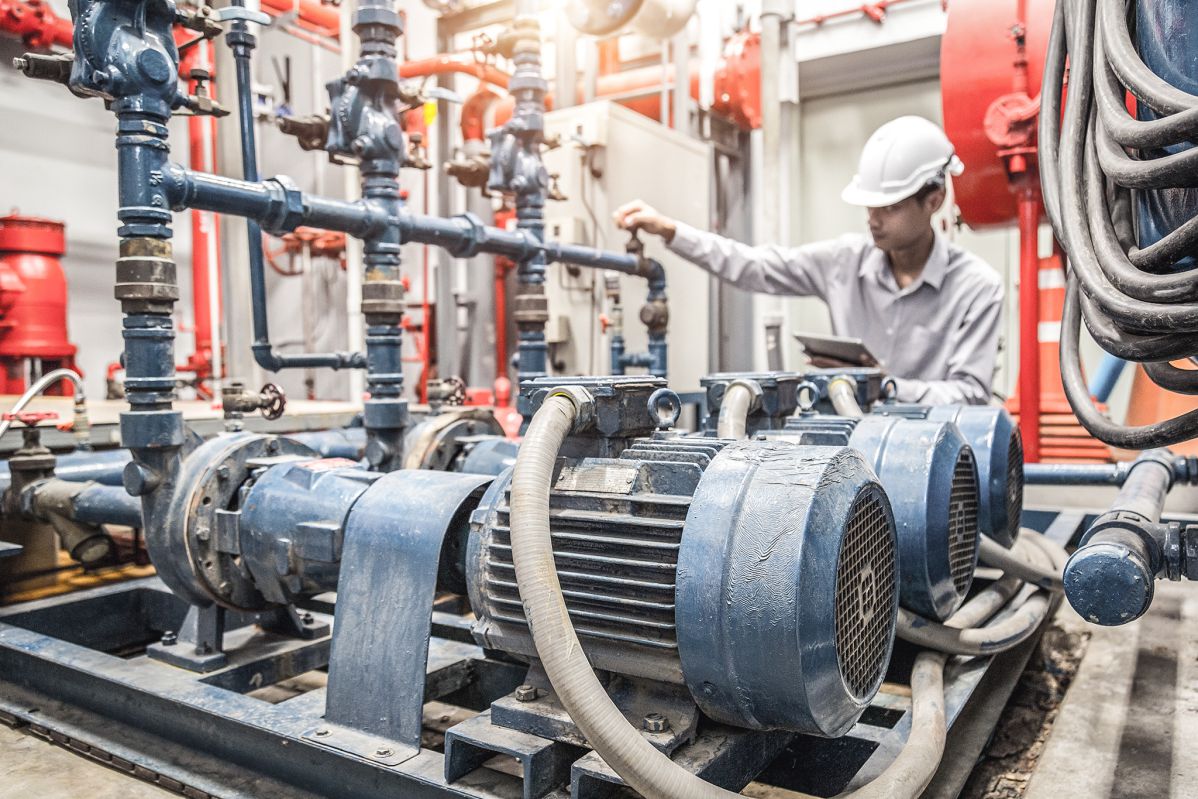

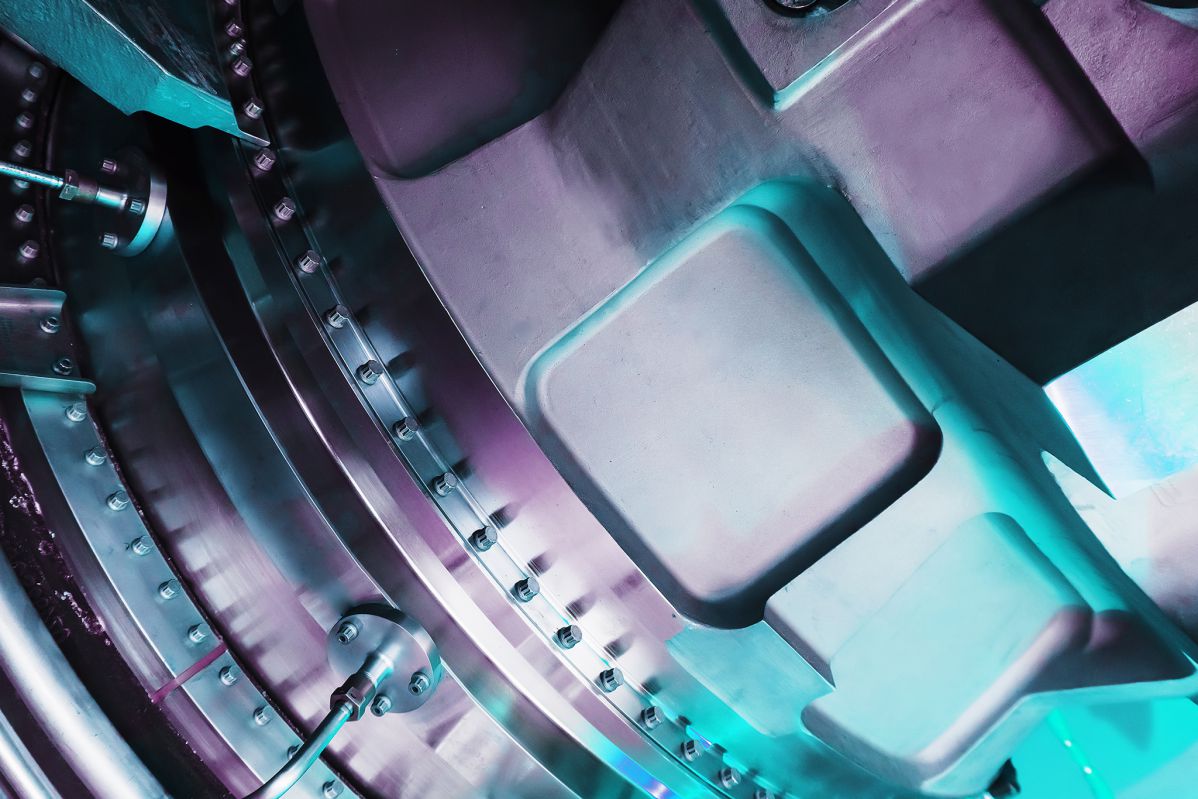

The Non-Drive End (NDE) of a propane compressor within a prominent Oil and Gas company in Qatar exhibited elevated temperatures, contrary to an MPC (Membrane Patch Colorimetry) test result of 7.5. The bearing temperatures recorded in the range of 76-84°C surpassed the stipulated warning limit of 70°C, requiring a thorough investigation. Subsequent physical examination of the bearing housings revealed substantial rubbing and deposits on the inner walls.

Solution

With the help of Petrotec, Fluitec’s Boost VR™ was added to the system and the ESP VITA™ also attached in a kidney loop to help remove the deposits from the system.

Results

Within one week of initiating the integrated treatment protocol, MPC values diminished, leading to stabilized temperatures. Approximately five months later, the ESP VITA III unit was disengaged from the system, resulting in sustained bearing temperatures below the 70°C threshold. Subsequent physical examination of the bearing housings revealed a pristine condition, devoid of deposits.