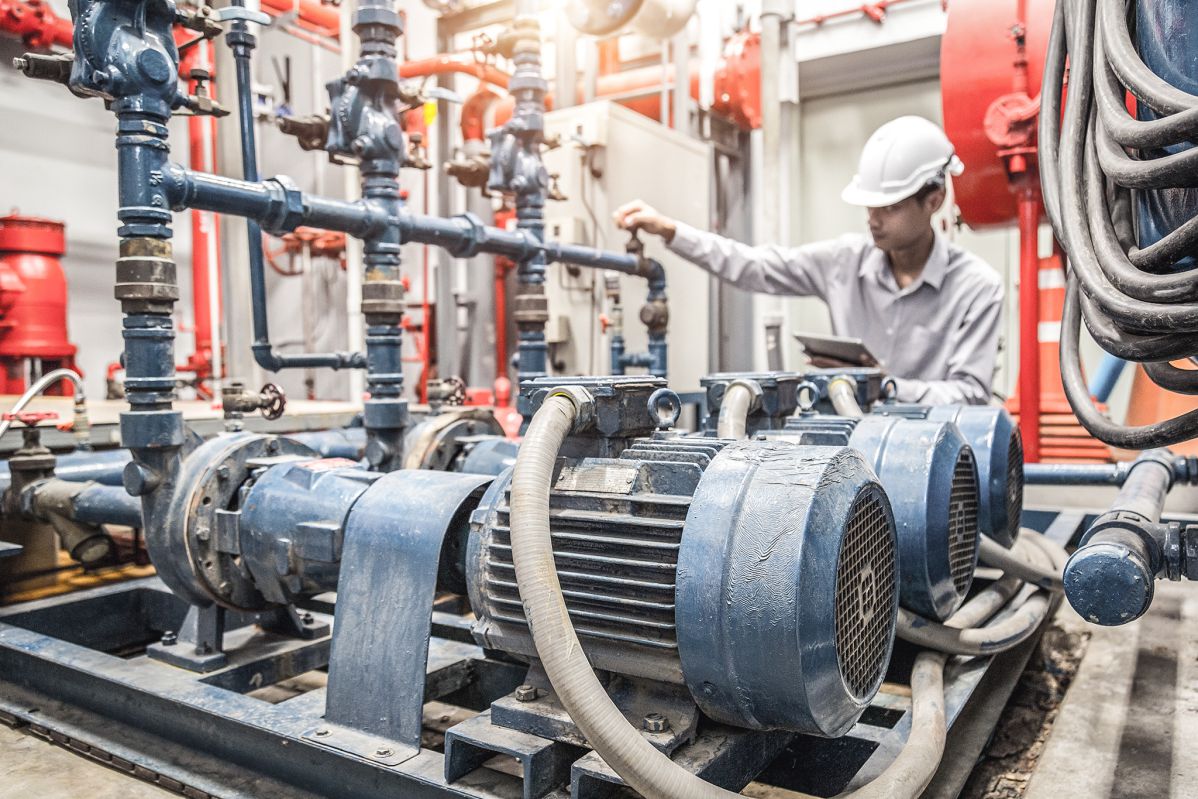

Preventing Downtime with Fluitec Legacy ESP at a Gas Treatment Plant

A gas treatment plant was facing axial bearing deposits, rising temperatures, and severe oil degradation with MPC levels over 30 and amine levels below 20%. These issues reduced efficiency and risked costly unplanned downtime.

Fluitec’s Legacy ESP solution was installed, immediately reducing MPC values to 10 and normalizing bearing temperatures. With regular filter changes, the system has remained stable for more than 10 years—avoiding shutdowns and ensuring reliable operations. The result: sustained performance and $120,000 in cost savings.

Problem

The Client began experiencing axial bearing deposits and increases in temperature at their gas treatment plant. Oil analysis showed MPC levels in excess of 30 and significant declines in the presence of Amines, below 20%! This negatively impacted on the efficiency of the plant and threatened unplanned downtime or even shutdowns.

Solution

Fluitec’s Legacy ESP was installed on the system and there was an immediate decline in the MPC values to 10. The Legacy ESP unit remained on the system and the filters were changed accordingly. This allowed the system to maintain normal MPC levels and reduce the temperatures on the axial bearings for more than 10 years!

Results

After installation of the Legacy ESP system there was a decline in MPC values to 10 and these were maintained within the normal range for the next ten years with appropriate filter changes. The temperatures on the system have been normalized and there are no threats of an unplanned shutdown or downtime.