One-Stop-Shop to Keep your Oil Clean Healthy and Contaminant Frees

We are helping companies reduce mechanical and fluid problems with various filtration solutions:

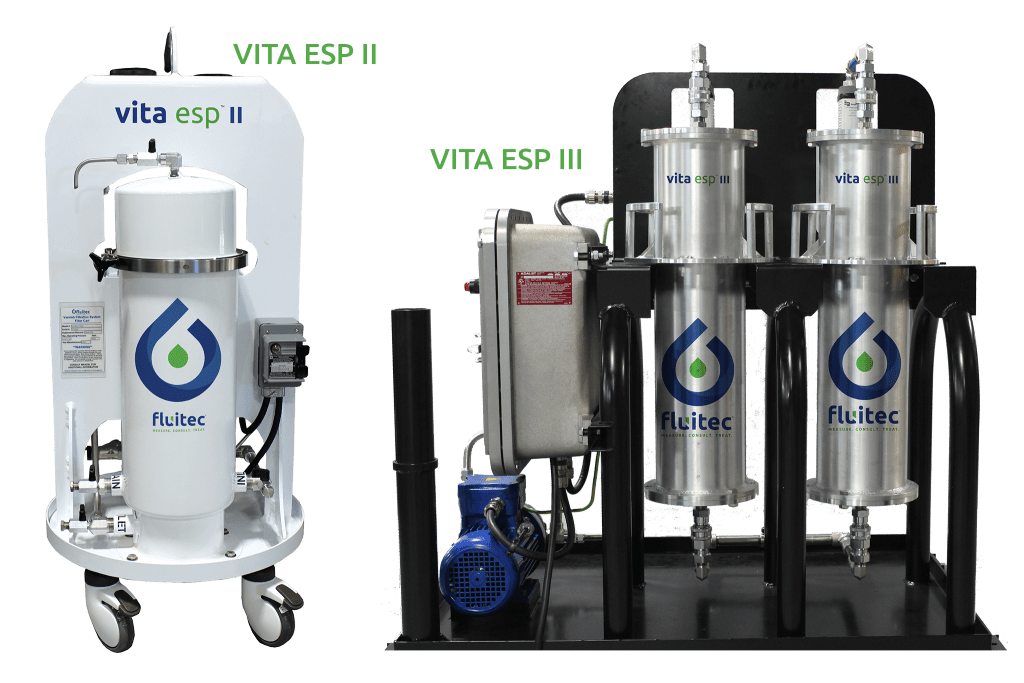

- ESP – Varnish Mitigation – Chemical Filtration

- Endure IX – Acid scavenging for Phosphate Ester Fluids

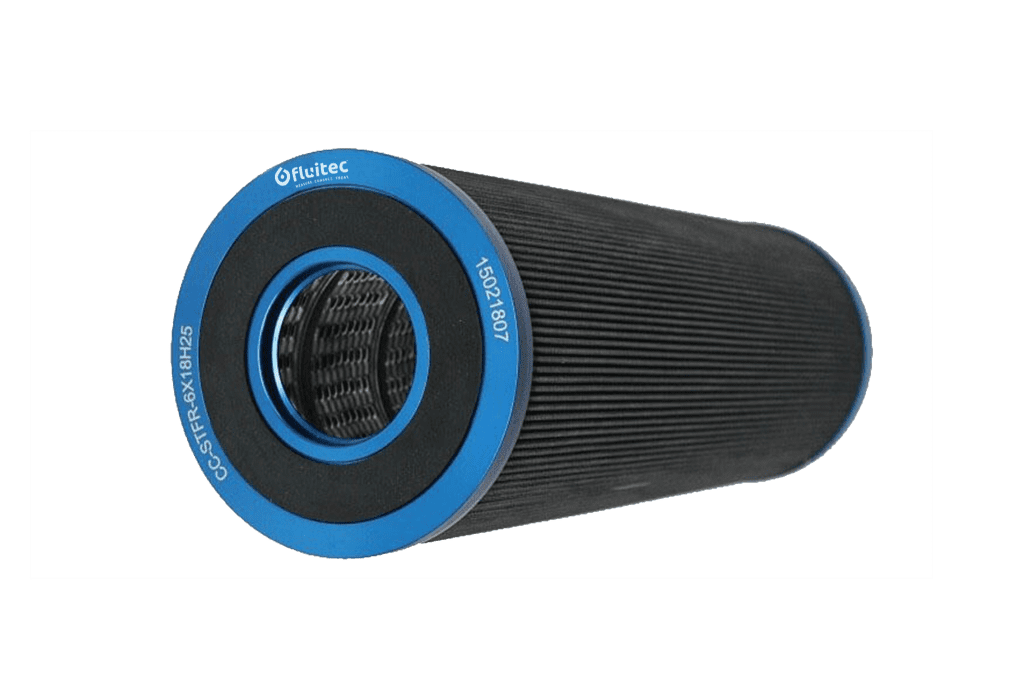

- Particulate Filters

- Depth Media Filters

- Spark Free – Electrostatic Discharge Filters

Each type of filter has specialized filtration techniques to solve specific but common problems, but together they help transform your lubricating or hydraulic oils into Fill4Life™ Fluids.