Brochures

Learn more about how our Vita ESP solutions can help.

Case Studies

Read about ESP in action.

Learn more about how our Vita ESP solutions can help.

Read about ESP in action.

You have bigger things to worry about than free-radicals and oil degradation molecules forming and depositing in your system.

Don’t wait until you have a deposit problem which requires excessive money, time and energy to solve.

ESP technology relies on the principles of “chemisorption.” ESP selectively removes oil degradation products that are in suspension or in solution without disturbing the fluid’s additive system. For optimal performance, ESP media is fully customized for each application and is selected based on oil type and condition.

As oil degradation byproducts (depleted antioxidants and oxidized base oil) make contact with ESP media, the specific mix chemically targets and removes the contaminants through strong adsorption forces. This ensures it will not be released back into the oil. ESP has a high capacity as it uses the full volume of the media, not just surface area.

Don’t take our word for it, download the Siemens technical article. (HINT: Check out the last page of the document)

The tests that provide the highest value in predicting turbine oil varnish are the individual antioxidant monitoring and Membrane Patch Colorimetry MPC™ in combination with particle counting.The earliest sign of oil degradation is detected with voltammetry (RulerView™ method) since the antioxidants are the most reactive species in turbine oils and are the first to deplete.The most important test to predict varnish formation is the Membrane Patch Colorimetry test, which measures the color of the sub-micron oil degradation products, as well as particle counting. It is preferential to use these tests together to provide a more complete picture of the varnish tendencies of the turbine oil.

Fluitec’s Vita ESP™ Systems provide you with maximum flexibility to control contaminants in your critical lubrication systems. The Vita ESP allows you to remove the most damaging types of contaminants in your fluid.

Multi-Purpose Filter housing can accommodate ESP, Endure IX™ and Depth Media elements. The system can be easily configured depending on your condition and application. Can also accommodate other Fluitec filtration technologies such as particulate, water adsorption, and SparkFree™ filters.

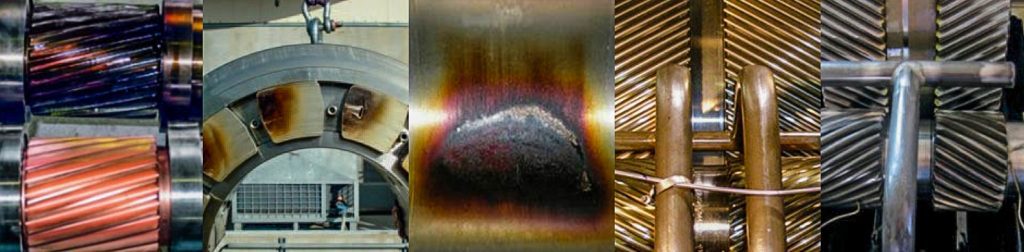

Mitigate the damaging effects of Sludge & Varnish using Fluitec’s patent-pending Electrophysical Separation Process™ (ESP) technology. Proven technology on hundreds of installations across 5 continents.

Efficiently remove dirt, debris and wear metals using high efficiency Depth Media down to 3 microns. Will help maintain excellent system cleanliness.

Our ENDURE acid scavenging technology removes all phosphate ester fluid degradation products, such as acids, gels and varnish.

For best overall performance and a Fill4Life™ lubrication system, or to get the most out of cleaning your system, we recommend ESP and our Boost product line.

Use Fluitec’s Vita ESP™ delivery systems to remove deposits, sludge and varnish from the oil while Boost AO™ replenishes the antioxidants.