Tech Deployment Track – Launch Alaska

In Launch Alaska’s Tech Deployment Track, selected climate tech startups from around the world work annually from September through April with a panel of industry experts, mentors, decision-makers and connectors to set ambitious goals and aggressively move toward securing and deploying projects in Alaska. The program helps startups prioritize and progress on customer discovery, market fit and project plans in partnership with Alaska customers, subject matter experts and key stakeholders. Companies remain in the Tech Deployment Track program as long as they demonstrate continued traction toward project deployment in Alaska.

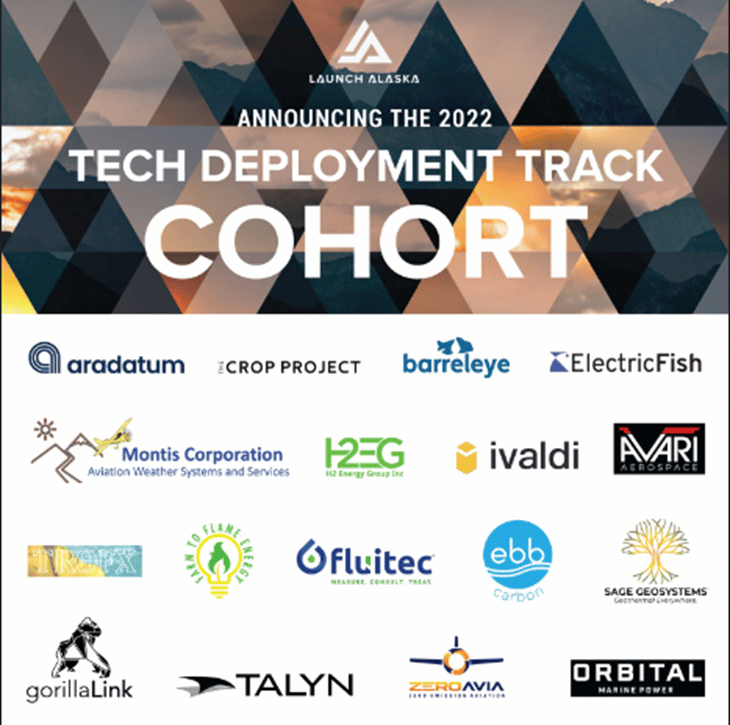

This year, Fluitec was selected among 13 Climate conscious companies to participate in the 2022 Accelerator Cohort. We will help to continue connecting globally scalable solutions to Alaska’s complex climate challenges. The aim is to deploy a project which is focused on the decarbonisation of Alaska’s energy, transportation and industry sectors.

Fluitec is aligned with the Industry Vertical and employs the conversion of industrial lubricants and hydraulics to Fill-for-Life™ fluids. These fluids reduce CO2 emissions and waste oil while saving money. This is largely based on our Solvancer® technology.

The Fill4Life Fluids

The Fill4Life concept changes the perception of oil as a consumable into that of an asset as it provides more return on the value it brings to the site. Fluitec’s products have been integrated into power generation, oil & gas and manufacturing industries globally. These cost-efficient products can systematically reduce power-usage and lubricant consumption thereby reducing waste and lowering CO2 impact. Our Boost AO™ & Infinity TO™ have been awarded Solar Impulse Foundation’s “1,000 Solutions Challenge”.

Infinity TO offers a 10 year oil life guarantee. This translates to a reduction of up to 50% in oil, drain, and maintenance costs. In more than 10 years, 58,000 tonnes of CO2 emissions and 22 million liters of turbine oil can be saved by switching to this product. Waste can be reduced by as much as 20 million kilograms! By extending the life of the oil, the ROI on the product can occur within the first few years of use. Since consumers will now be utilizing less lubricants, there is also a lower raw material extraction demand.

The 10 year performance guarantee of Infinity TO ensures that the MPC (Membrane Patch Calorimetry) value stays in the normal range (maximum MPC of 20) for ten years. No varnish mitigation equipment is required during the lifetime of this product. As such, users should not experience any performance issues on turbine bearings, servo valves, gears, hydrogen seals, heat exchangers or any other piece of equipment as it relates to varnish. This product will also reduce costly downtime and eliminate the need for flushes which significantly impacts the environment.

Boost AO on the other hand is customized specifically for turbine oil and designed to rebalance the additive system. Its formulation and treat rate is developed based on the original oil formulation and current condition of the in-service oil. These tailored additive components are blended into a concentrate with a similar viscosity of the in-service fluid. This eliminates the need for special equipment on site to administer this product.

However, not every in-service oil is suitable for additive replenishment. If there are oil degradation products, mixed formulations or contamination, then it may not be appropriate to replenish this oil with the additives. Our scientists have developed the Qualification test which is required before administering Boost AO. This helps us to develop a customized Boost formulation and blend Boost AO to a specified treat rate with the in-service oil. Compatibility testing is also performed using the ASTM D7155 standard.

DECON is also another product which utilizes the Solvancer technology. This assists in quickly dissolving varnish and organic deposits from the internals of machines. It essentially decontaminates the machines. As such, it reduces the oil’s varnish potential while offering long-term protection against deposits and sludge. This drastically eliminates the downtime caused by varnish and the need to replace the oil after it has become riddled with varnish and deposits.

These products can be used with the VITA ESP (Electrophysical Separation Process) to further aid in the removal of deposits and to maintain a clean oil. The Solvancer family also includes; DECON AO, DECON AW and Boost VR+ which all aid in the removal of deposits and / or rebalancing of additives to keep the oil in a healthy state and prolong its life. These all contribute to reducing the GHG emissions and the traditional high volumes of waste oil from these industries.

About Launch Alaska

Founded in 2016 and based in Anchorage, Alaska, Launch Alaska is a non-profit deployment accelerator focused on helping climate tech companies find customers, deploy projects, get revenue and make an impact in Alaska.

Founded in 2016 and based in Anchorage, Alaska, Launch Alaska is a non-profit deployment accelerator focused on helping climate tech companies find customers, deploy projects, get revenue and make an impact in Alaska.

They work side-by-side with some of the brightest climate tech companies in the world to deploy innovations that tackle the planet’s biggest challenges. Launch Alaska works with stakeholders to deploy projects that solve challenges in the energy, transportation and industry sectors. This involves bringing climate tech startups to Alaska via the Tech Deployment Track and project facilitation through their Deployment Team.

**********************************************