Improving Hydraulic System Efficiency with Mobil™ Solvancer® Oil-Soluble Cleaner: A Case Study at a South Carolina OSB Mill

by Chris Vander Neut, ExxonMobil; Greg Livingstone, Fluitec; Micky Jones, Fluitec

Introduction

Hydraulic presses in Oriented Strand Board (OSB) mills are central and indispensable to OSB production. They exert immense, uniform force required to compress wood strands and resin into durable panels, operating under exacting temperature and pressure conditions. The performance of hydraulic presses depends critically on the quality and condition of the hydraulic oil.

The Vital Role of Hydraulic Oil

Hydraulic oil in OSB presses serves multiple roles:

- Power Transmission: Hydraulic oil transmits power from pumps to press cylinders, enabling precise compression.

- Lubrication: Reduces friction in pumps, valve spools, and cylinders.

- Heat Transfer: Acts as a coolant, absorbing and dissipating heat from critical components.

- Sealing and Contamination Control: Prevents contamination ingress, maintaining system integrity.

Hydraulic Oil Failure: Oxidation and Varnish

Despite its crucial role, hydraulic oil is susceptible to failure, especially due to oxidation and subsequent varnish formation. Oxidation, a reaction with oxygen accelerated by heat, pressure, moisture, and catalytic metals, depletes antioxidants and generates harmful byproducts.

Varnish, an insoluble, sticky deposit formed from these oxidation byproducts, accumulates on critical components, especially servo and proportional valves. This buildup is analogous to cholesterol plaque in arteries, restricting fluid flow, reducing responsiveness, and increasing operational risks.

Operational Impact of Oil Degradation

When hydraulic oil fails:

- Press Performance Suffers: Reduced valve responsiveness leads to inconsistent press forces, resulting in poor board quality and defective products.

- Maintenance Costs Escalate: Varnish buildup necessitates frequent component replacements, system flushes, and increased downtime.

- Energy Efficiency Drops: Oxidized, varnish-contaminated oil increases viscosity, and blocks oil flow channels raising power demands and operating costs.

- Safety and Environmental Risks Increase: Potential leaks and compromised components present significant hazards. Oxidize oil is known to deteriorate seals leading to more leaking and increased risk.

A Breakthrough Solution: Mobil™ Solvancer® Oil-Soluble Cleaner

To combat these challenges, Fluitec® N.V and Mobil™ developed Mobil™ Solvancer®, an innovative oil-soluble cleaner. Mobil Solvancer® oil soluble cleaner dissolves varnish deposits effectively, analogous to a solvent clearing blocked pipes, immediately restoring system responsiveness. It also provides long-term protection, minimizing varnish recurrence, improving servo valve response times, and extending equipment life.

An OSB Mill in South Carolina: A Mobil™ Solvancer® Oil-Soluble Cleaner Success Story

A major OSB manufacturer in South Carolina demonstrated the exceptional longevity and resilience of Mobil DTE™ 25 and Mobil DTE™ 25 Ultra oils, which remained in service for nearly 15 years in a 44,000-gallon press hydraulic system, well beyond the typical oil life expectancy for this demanding application. Throughout this extended period, the system endured a prolonged shutdown, over a decade of continuous manufacturing operations, repeated high-temperature excursions, persistently elevated particle counts, and multiple high water ingress events. Despite these extreme conditions, the oils continued to provide operational support until the customer was finally able to schedule an oil change. As the oil aged and system stress accumulated, the frequency of servo valve failures increased, reaching a peak of six failures every three weeks just prior to the introduction of Mobil™ Solvancer® oil-soluble cleaner. At that point, valve-related maintenance was costing the facility approximately $40,000 per month.

Addressing the Challenge

The Mobil™ Maximum Service Analysis test revealed high varnish levels indicated by elevated Membrane Patch Colorimetry (MPC) values (66ΔE), along with increasing Ultracentrifuge values, increasing Total Acid number (TAN), and decreasing Rotating Pressure Vessel Oxidation Test (RPVOT) performance. The mill implemented a 5% treatment rate of Mobil™ Solvancer® oil-soluble cleaner (approximately 40 drums) combined with enhanced kidney-loop filtration to remove particulate material observed through high ISO particle count results.

Results Achieved

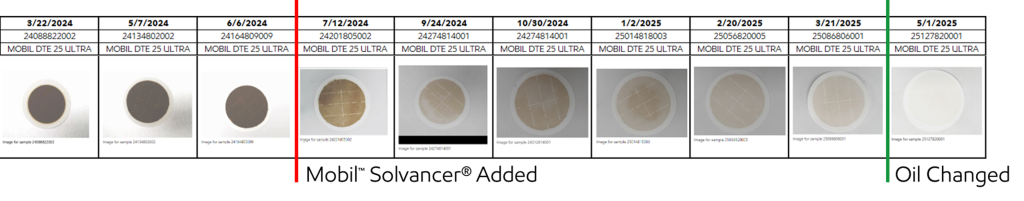

After Mobil™ Solvancer™ oil-soluble cleaner addition to the oil system, measurable results* were observed:

- After 3 weeks, MPC values were cut in half

- After 2.5 months, MPC values dropped from 66ΔE to 26ΔE

- After 8 months, MPC dropped from 66ΔE to 14ΔE, representing a 73% total reduction

- Ultra Centrifuge (UC) ratings improved from 4 to 1 and were sustained over the remaining oil life

- Servo valve failures decreased from six per month to zero, showcasing substantial reliability improvements.

- Both TAN and RPVOT were not impacted by Mobil™ Solvancer™ (testing showed a measurable improvement)

| Date Sampled | MPC ΔE | UC Rating | Notes |

| 2/2/2024 | 33 | 2 | |

| 2/22/2024 | 52 | 3 | |

| 3/22/2024 | 64 | 3 | |

| 5/7/2024 | 65 | 3 | |

| 6/6/2024 | 66 | 4 | Final sample before Mobil™ Solvancer® added |

| 7/12/2024 | 33 | 1 | 3 weeks after Mobil™ Solvancer® added |

| 9/24/2024 | 26 | 1 | |

| 10/30/2024 | 18 | 1 | |

| 1/2/2025 | 20 | 1 | |

| 2/20/2025 | 14 | 1 | |

| 3/21/2025 | 16 | 1 | Final sample before oil change |

| 5/1/2025 | 3 | 1 | 4 weeks after oil change |

Figure 1. Visual and graphical Membrane Patch Colorimetry (MPC) test results showing progressive varnish removal in the OSB mill’s hydraulic system following the addition of Mobil™ Solvancer®. Noticeable improvement began within 3 weeks, with patch color lightening steadily over the 8-month operational period prior to the scheduled oil change, indicating effective varnish mitigation.

Future Outlook

With proven success, the mill scheduled a complete system oil change to Mobil DTE™ 25 Ultra and plans to install permanent high-efficiency filtration in 2025, helping promote long-term system integrity and performance.

Conclusion

Effective management of hydraulic oil conditions is crucial for maintaining optimal productivity and reliability in OSB mills. Mobil™ Solvancer® oil-soluble cleaner demonstrates exceptional performance, significantly reducing varnish deposits, enhancing system efficiency, reducing maintenance costs*, and ensuring consistent product quality. As demonstrated by this mill’s experience, proactive maintenance coupled with Mobil™ industry-leading hydraulic oils and advanced oil analysis testing can help transform operational reliability in industrial hydraulic systems.

*Individual results may vary based on operating conditions.

©2025 ExxonMobil. All trademarks and service marks used herein are trademarks or registered trademarks of Exxon Mobil Corporation or one of its subsidiaries.

©2025 Fluitec. Fluitec and Solvancer are registered trademarks of Fluitec NV or one of its subsidiaries.