The Role of MPC & RULER in Monitoring the Presence of Varnish

Condition monitoring is vital when trying to understand the health of your equipment. Different types of equipment require varying tests and frequencies. However, there are a number of tests which can be performed to determine the health of the lubricant. Typically, these traditional tests are used to detect the onset of varnish which is a prevalent challenge faced within the industry. The MPC and RULER tests are designed specifically for the detection of varnish and its precursors.

Getting into the specifics of MPC!

The regular suite of oil analysis tests such as viscosity, oxidation by FTIR can show some change in the oil’s condition but the MPC and RULER tests really get into the details. The MPC test stands for Membrane Patch Calorimetry (ASTM D7843). This is a two-step process involving filtration and then colour measurement.

To perform the MPC test, 50ml of the used lubricant is diluted with 50ml of petroleum ether. This mixture is then filtered through a 45mm nitrocellulose patch. The patch is rinsed with petroleum ether and dried. Next the intensity and colour of the patch is measured against a control patch. A spectrophotometer is used to calculate the colour difference. This value is then matched against the values on the MPC scale to determine the oil’s propensity to form varnish.

In fact, this test confirms the quantity of soft contaminants in the oil and the colour can be related to the type of deposit being produced. However, there is usually a longer turnaround time when these samples are sent to the lab. There is an onsite equipment which was developed by Fluitec called the MPC Colour Handheld Visual Spectrophotometer. This produces results in 1.8 seconds and can produce results in both csv and pdf formats.

Case study – importance of MPC testing

Within the automobile industry, there isn’t a high usage of the MPC test to detect the presence of varnish. However, a major automobile manufacturer in Slovakia began experiencing valve sticking on their hydraulic presses and saw a lot of failing pumps and seal locks. Varnish began accumulating within their system without their knowledge since no MPC tests were being performed.

MPC tests were integrated into their condition monitoring systems. Varnish Mitigation systems were then employed but there was a very high consumption of filter elements after these were disconnected. The team also noticed that the MPC levels rose quickly after disconnection which still indicated the presence of varnish in their system.

Fluitec’s DECON was added at a 3% treat rate to the system and it immediately experienced a steady decline in varnish levels. The valves were no longer stuck! They also added DECON AW to help in maintaining the antioxidant levels and control the formation of deposits. This actually resulted in $1.3M in savings.

Understanding RULER

RULER represents Remaining Useful Life Evaluation Routine. In this test, Linear Sweep Voltammetry is used to quantify the remaining antioxidants in the lubricant. Current is passed through the lubricant and the voltage is increased over a set timeframe. Antioxidants will accept electrons at particular voltages which produce peaks to get the RULER graphs. These results show the quantities for both the primary and secondary antioxidants (hindered phenolic and aromatic amine antioxidants).

There are four ASTM standards written around RULER, namely; D7590, D6971, D6810 and D7527. Additionally, there are a few industry guidelines which support it as well including; ASTM D4378, D6244and DIN – VGB M 416. Major equipment OEMS such as Siemens and GE recommend RULER as part of a condition monitoring program.

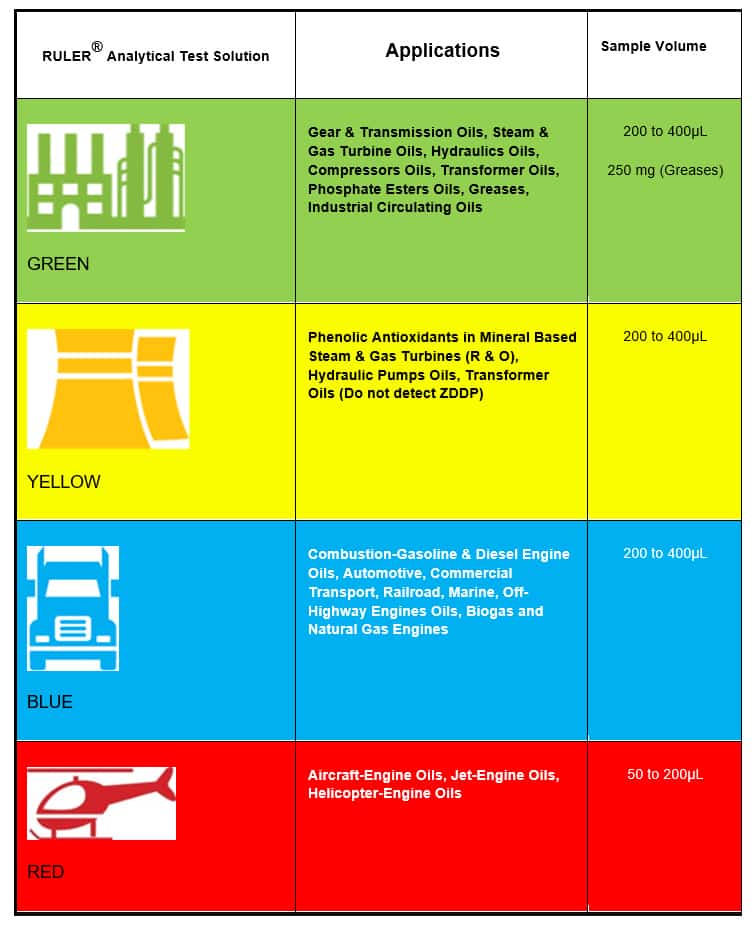

Typically, RULER tests are done in labs and this may take a long turnaround time but Fluitec has developed Ruler® ViewTM. This allows the power of the RULER test to be taken out into the field with this portable technology. Users need to be aware of which of the solutions should be used. Here’s an overview of the different colours of the solutions and their applications.

These test solutions are provided in 7 milliliter glass vials with color-coded caps or labels, which attach easily to the RULER® View Probe. The Test Solutions are convenient for remote-field testing. Each vial contains 5 milliliters of Ruler solution such as Red, Green, Blue or yellow with dissolved electrolytes (vital for the extraction and voltammetric detection of the antioxidants); and one gram of sand for agitation and for breaking micro droplets. When the vial is shaken to properly mix the oil sample with the Test Solutions, the sand will help to separate the oil from the antioxidants as the sand settles (fine sand), whereas the coarse sand will adhere oil and debris and the antioxidants will remain in the solution for testing.

These test solutions are provided in 7 milliliter glass vials with color-coded caps or labels, which attach easily to the RULER® View Probe. The Test Solutions are convenient for remote-field testing. Each vial contains 5 milliliters of Ruler solution such as Red, Green, Blue or yellow with dissolved electrolytes (vital for the extraction and voltammetric detection of the antioxidants); and one gram of sand for agitation and for breaking micro droplets. When the vial is shaken to properly mix the oil sample with the Test Solutions, the sand will help to separate the oil from the antioxidants as the sand settles (fine sand), whereas the coarse sand will adhere oil and debris and the antioxidants will remain in the solution for testing.

Case Study – the significance of RULER

One customer wanted to extend the life of the oil in their Steam turbine by 2-3 years. They believed that through testing, they could accurately gauge the health of the oil and used the following tests; Air release, Foam, Colour, Viscosity, Oxidation, TAN, RULER. Interestingly enough, the test which was most impactful in making the decision on whether to extend the life of the oil or not was the RULER test! This test showed the depletion of antioxidants before any of the other tests picked up changes to the oil.

As seen above the antioxidants had significantly depleted into the warning zone (25) indicating that oxidation was occurring. The viscosity and TAN values did not change considerably to indicate the onset of oxidation. In this case study, the RULER test helped the operators to fully understand that the oil was oxidizing and effectively plan for shutdowns.

MPC & RULER – the way forward

While traditional oil analysis tests can help in monitoring the health of the oil, the MPC & RULER tests are ideal for detecting the presence of varnish. As shown above, the MPC test can aid operators in detecting the formation of deposits through the MPC Color Handheld Visual Spectrophotometer in a matter of seconds. Additionally, the Ruler View can assist users in acknowledging the depletion of antioxidants to detect the onset or ongoing process of oxidation. These two tests are ideal for those wanting to understand the health of their equipment’s lubricant and detect the presence of varnish.