Eliminating Deposits and Rebalancing Antioxidants – Can It Be Done?

The Quest for a solution

During the life of a lubricant, it usually undergoes aging and depletion of its additives. If a lubricant is subjected to particular environmental and operational conditions then it can start to degrade and produce deposits. Traditionally, if deposits start appearing or the antioxidants get depleted, the lubricant is rendered as failed and is disposed. This leads to a new charge of oil being ordered, flushing procedure carried out and the scheduling of all the logistics required to have the system returned to functionality. What if we didn’t have to dispose of the lubricant in the first place? Perhaps, we could have used some method of eliminating the deposits formed and even rebalancing the antioxidants in the lubricant? Does such a product exist?

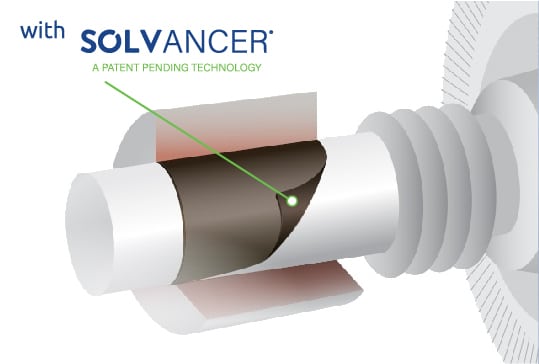

DECON AO™ with Solvancer®

DECON AO has been formulated to effectively dissolve varnish thus quickly and safely decontaminating the system while replenishing the antioxidants in the oil. It also enhances deposit control performance ensuring that deposits remain in solution and do not adhere to servo valves, seals, bearings or any of the systems equipment. Typically, when varnish adheres to these components, the system’s temperatures rise (due to varnish’s insulating nature) and they reduce their efficiency by blocking the small clearances. DECON AO ensures that there is long term deposit control performance in the lube system to eliminate these challenges.

All lube systems are not created equal and a standardized solution for antioxidant replenishment cannot be readily adapted. As such with DECON AO, the scientists at Fluitec determine the treat rate and formulation based on the original oil formulation and the condition of the current in-service formulation within your equipment. Once these have been assessed, DECON AO can be directly added to your equipment at your site without the need of special equipment.

What are the benefits of DECON AO?

The first and foremost benefit of using DECON AO is the simplicity of having one product that replaces several products and services while allowing users to save money. Here’s a full list of the benefits that DECON AO provides:

- Extension of Oil life – Oil life gets extended beyond the traditional 2-5 year capacity as the antioxidants are replenished and deposits are kept in solution.

- Transformation of your oil from a consumable into an asset – oil will no longer be changed on a rotational basis hence it is no longer a consumable.

- No-risk guarantee & 100% Success rate – DECON AO is tested for compatibility and success before it enters your system ensuring that it will perform when added.

- Superior seal compatibility compared to mineral oils – does not make changes in mass, volume, modulus or strength.

- Reduces carbon emissions through demand reduction – after adding DECON AO to your lube, it becomes a Fill4Life lubricant. Therefore reducing the entire process of buying new oil, getting it delivered to the equipment and even the production of the oil. It creates a sustainable process within your equipment.

- Increases RULER & RPVOT Test results – antioxidants are sacrificial in nature and are therefore depleted during the life of an oil. With DECON AO, it maintains the antioxidant level such that there is always an acceptable, healthy presence of antioxidants.

- Rapidly reduces the oil’s varnish potential as measured by MPC (Membrane Patch Calorimetry), UC (Ultra Centrifuge) and Particle Counts – this is due to the deposit control factor in DECON AO.

- Excellent oxidation stability and / or deposit control characteristics – through the advanced formulation of the DECON AO with Solvancer the oil is now enhanced to ensure that deposits do not come out of solution and that the antioxidant levels are maintained at acceptable levels.

- No adverse impact on the in-service oil’s performance (particularly the air release, foam, demulsibility etc) – this is ensured through the prior testing of the DECON AO with the current in–service oil before placing it in the system.

What a warranty!

Fluitec has warranted that DECON AO is compatible with existing turbine oil and will not cause any adverse performance effects to the in-service lubricating oil, provided simulation testing is performed. When DECON AO is added to a qualified in-service oil, it is warranted to meet the oxidative and viscometric performance requirements of OEM and international Standard Body turbine oil specifications including:

- Alstom HTGD 90117

- GEK 32568J, GEK 27070, GEK 28143A, GEK 46506D

- Siemens TLV 9013 04, Siemens Westinghouse M Spec 55125Z3

- Solar ES 9-224

- ASTM D4304

- British Standards Institution BS 489 and

- DIN 51515.

This proves the confidence and assurance that Fluitec has placed in DECON AO as they have gone the extra mile to ensure that it meets the approvals of OEMs and technical societies.

Achieving Fill4Life™

Antioxidants are sacrificial in nature. When varnish is present, these antioxidants get depleted however DECON AO replenishes those antioxidants but the varnish molecules may still remain in solution. The ESP (Electrophysical Separation Process™) system created by Fluitec ensures that these varnish molecules are removed from the system so that they can no longer cause any harm. The ESP system coupled with the presence of DECON AO truly turns the lubricant into an asset and makes the system a real Fill4Life.

Fluitec’s Fill4Life program was designed to extend the life of our customers’ capital equipment and fluids while supporting their quality and maintenance programs through the minimization of overall costs and waste. Some of the key aspects of a Fill4Life fluid is the minimization of contaminant ingression, removal of oil degradation by-products and replenishment of sacrificial additive components while monitoring the health of the fluid. All of these are achieved through the combined use of DECON AO and ESP.