DECON HD – The Solution for Your Heavy Duty System!

Have you ever had to shut down equipment because there was varnish in your system? These shutdowns can be quite costly especially if you’re dealing with critical equipment. Gearboxes and heavy duty systems are no exception. The shutdown of a heavy duty system can take a longer time to get back online due to their complexities and safety risks involved with these types of equipment. This is one of the main reasons why we’ve created DECON HD, ideally suited for systems utilizing ISO 150-320 grades of oil.

DECON HD is part of the DECON family and is engineered with Solvancer® (a patent pending technology). It has been designed to decontaminate systems and protect the oil from forming varnish while providing long term deposit control. It can make an immediate impact on a system and dissolve varnish which can lead to rapid reduction in temperatures and possibly avoiding an unplanned shutdown. Before getting into more details about DECON HD, let’s take a step back and find out more information about the entire family.

The DECON Family

The DECON family consists of four products which all carry Solvancer as the main ingredient. What sets these products apart is their applications to various situations. Let’s take a closer look at their differences below:

- DECON – This is the main product and can be used in any system to decontaminate it and help keep deposits in solution. Ideally, its treat rate is between 3-5% and should be used for applications utilizing grades of ISO 100 or lower.

- DECON HD – ideally suited to decontaminate systems using ISO 150-320 This has a higher treat rate of 6-10% (due to the viscosities involved). Typically, these types of viscosities are found in industrial gearboxes.

- DECON AW – Hydraulic oils need to be clean due to the tight tolerances but they also undergo a lot of wear. Hence the antiwear property usually diminishes very quickly in some hydraulic oils. DECON AW is suited for hydraulic systems experiencing high levels of varnish and wear. It keeps the deposits in solution while also adding another level of protection with the antiwear properties. Usually, a treat rate of 3-5% is used in this application.

- DECON AO – Most oils undergo oxidation which in turn produces deposits. During this process, the antioxidants often become depleted and the base oil can undergo degradation. DECON AO was designed to prevent long term deposits and replenish antioxidant levels in the oil. This typically uses a treat rate of 3-5%.

The DECON HD Specifics

DECON HD is a blend of Group IV and V chemistries with a flash point of 216°C. It has a Risk Free Guarantee to have no compatibility impact on the chemistry of the in-service oil such as the demulsibility, air release or foaming characteristics. In fact, it can rapidly reduce the oil’s varnish potential, has excellent oxidation stability and deposit control characteristics. This makes it ideal for heavy duty systems experiencing challenges with deposits.

FAQs

Here are some Frequently Asked questions about DECON HD:

How does DECON HD work?

DECON HD has been formulated with Solvancer®. This patent pending technology is solubility enhancing which gives DECON HD its properties. Solvancer has been engineered for non-detergent, API Group I-IV based lubricants. It is an API Group V synthetic oil which is miscible in lubricants and does not affect the additive system’s functionality.

When DECON HD is added to the system, it rapidly dissolves varnish from the machine using the enhanced solubility properties of Solvancer.

Is DECON HD compatible with other oils / products?

Yes it is! DECON HD is made with an API Group V synthetic oil which is miscible in lubricants. It also doesn’t affect the additive system’s functionality. It does not impact system materials such as seals, filters or paint.

Can DECON HD be used for different viscosity oils? Will it affect the viscosity of the current oil?

DECON HD is specifically designed for ISO 150-320 grades. Since this is typically added at a ratio of between 6-10%, it does not significantly affect the overall viscosity of the oil.

Where does the varnish go?

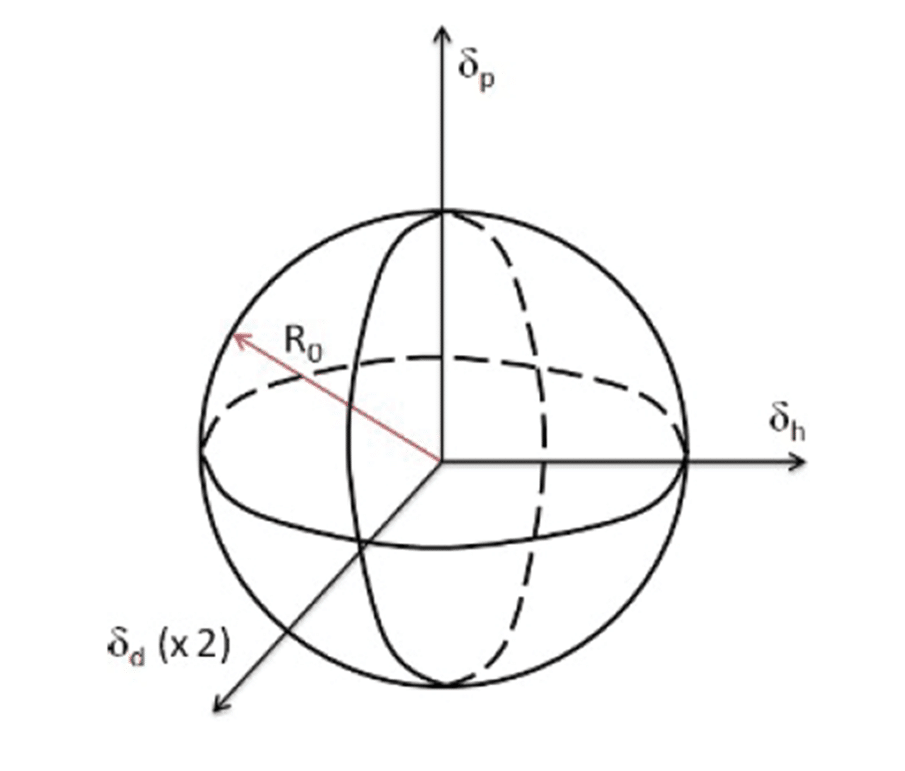

DECON HD is formulated with Solvancer. Solvancer is responsible for keeping the varnish in solution. This is based on Hansen’s solubility principle that “like” dissolves “like”. Oil degradation products are more polar than the non-polar state of the lubricant which derived them. The Hansen Solubility parameters model polarity, hydrogen bonding and dispersive forces on a 3 dimensional axis forming the Hansen Sphere. The effectiveness of solubility enhancers are defined by a sphere with a radius which encompasses oil degradation products. Once the properties of the varnish-causing contaminants reside in the sphere, they will effectively dissolve.

We must also remember the lifecycle of varnish, there is a double arrow between the solubility-precipitation-agglomeration-varnish formation steps. This indicates that even though varnish may be formed, it can be solubilized and return to its original solution. These reactions are reversible. This is how the varnish is returned to the oil in a soluble form through the use of DECON HD.

How long do I need to leave DECON HD in my system?

Typically, DECON HD has shown results within 24 hours of its addition to the system. There have been applications which took one month to see the decontamination of their system. This rate of results will differ depending on the amount of varnish present in the system and the treat rate of DECON HD. It’s best to contact one of Fluitec’s reps to allow them to properly assess your system and then make determinations on the ratio required.

Usually, DECON HD may be added to systems as a way of removing all the varnish before a system shutdown. This ensures that the system is clean and ready for the new fill of oil. It can also be used to prevent a shutdown of equipment due to large accumulated amounts of varnish. DECON HD can remain in the system and it will not negatively impact the function of the oil.

Is there a ratio to add DECON HD to the system?

The usual treat rate for DECON is between 6-10%. These treat rates have been used successfully on varying types of varnish in many systems and we have seen the systems being cleaned.

It’s best to contact one of Fluitec’s reps to allow them to properly assess your system and then make determinations on the ratio required.

Can DECON HD be used in new oil?

While DECON HD is usually used in oil which has been in the system for some time, it can also be added to new oil as it does not impact the properties of the oil. Its purpose is to dissolve any varnish which is formed by the oil.

Are there any implications of DECON HD traces remaining in the equipment?

DECON HD is usually added at a treat rate of 6-10% of the system’s volume. Thus if the system is drained, there is a very low probability that traces of DECON HD will remain in the equipment at high concentrations. Additionally, DECON HD is highly compatible with lubricants as well as materials within the system. Hence, if any traces of DECON HD remain in the equipment, there should be no compatibility issues with the lubricant being added to the equipment.

Can DECON HD be used in any industry?

DECON HD can be used once there is varnish in a lube system which uses oil within the ISO 150-320 grade range. This applies across industries however, there may be restrictions in the Food and Beverage or environmentally aware industries where spillage into the environment may be a concern. These can be guided by the regulations for these industries.

Can DECON HD be added to the system more than once?

Typically, DECON HD is added at a treat rate of 6-10% and its effects on the system are monitored. Should the need arise to add DECON HD a second or third time, a Fluitec rep should be contacted.

Please reach out to your Fluitec Rep if you have additional questions.