By Greg Livingstone, Amar Pradhan and Mary Moon of Fluitec International

By Greg Livingstone, Amar Pradhan and Mary Moon of Fluitec International

*This blog is an excerpt from the Wind Turbine Gearbox Oil Analysis Strategy whitepaper. To receive a copy of the full text, request by clicking here.

Wind turbines have the potential to generate enough power to meet growing needs for electricity, diversify sources of energy, and reduce consumption of water and emission of pollutants such as carbon dioxide. Barriers to widespread acceptance of wind turbines include their reliability and costs for operation and maintenance (O&M) of the equipment relative to alternative means of power generation. Lubricant-related failure, unexpected down time, and expensive unscheduled maintenance are problematic, especially for wind turbines in offshore locations. According to Wind Energy Update’s 2011 Operation and Management Report[1], as much as 66% of the O&M costs for some offshore wind turbines may be related to unplanned maintenance events. The Report notes that some wind turbine gearboxes are warrantied for 20 years but fail within 8 years. Gearboxes are critical components of wind turbines.[2] A research and development initiative to improve gearbox reliability, headed by the National Renewable Energy Laboratory (NREL), seeks to improve the design process for wind turbine gearboxes.[3] In addition, there is a growing need to efficiently manage the reliable operation and economical maintenance of in- service wind turbines now and in the future.[2-4]

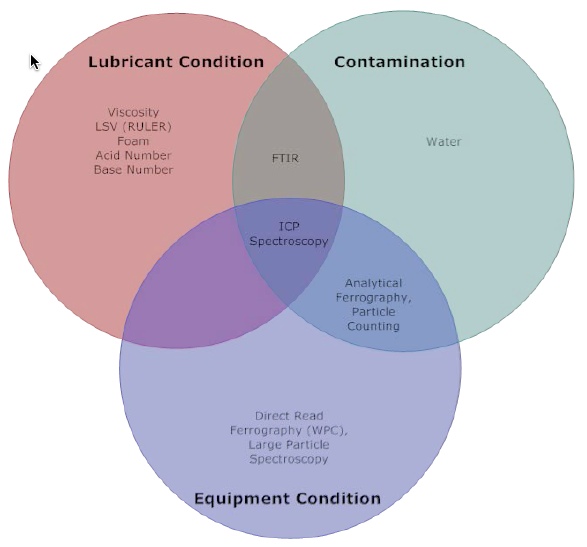

Oil analysis is a cornerstone of condition-based monitoring and reliability engineering for critical mechanical devices in manufacturing, aviation, and countless other applications[5,6]. Oil analysis refers to the collection and evaluation of samples of in-service lubricants in order to assess the condition of the oil and machinery, and inform decisions about their maintenance. In addition, oil analysis data can serve as a log of historical information about the condition of the fluid and equipment. Work is underway to develop methods to apply existing test methods[7,8] for oil analysis, and invent new ones, for wind turbines. This article recommends some useful oil analysis tests for routine evaluation of in-service gear oils in wind turbines, and some additional tests that can provide further insight as needed. Request the full white paper “Wind Turbine Gearbox Oil Analysis Strategy” by clicking here.

About Fluitec:

Fluitec provides customers and partners leading edge technologies and knowledge to realize optimum reliability and productivity of their lubricating assets. Our holistic approach maximizes the life cycle of rotating and hydraulic systems in an environmentally sustainable way. For more on Fluitec go to: www.fluitec.com or contact us at: +1.888.557.9575 or at info@flluitec.com

******************

About the Authors:

Greg Livingstone, VP Business Development for Fluitec International, g.livingstone@fluitec.com

Greg has been involved with optimizing lubrication programs for two decades. He’s a Certified Lubrication Specialist (STLE) and has held industry leadership roles in several committees including ASTM’s Turbine Oil Analysis and Problem Solving committee and STLE’s Power Generation and Wind Turbine technical groups. He has over 40 published papers focused on condition monitoring and contamination control.

Amar Pradhan, Chief Operating Officer for Fluitec Wind, a.pradhan@fluitec.com

Amar is an experienced entrepreneur having started, grown and sold businesses in the cleantech space. Amar started his career launching new products in the global automotive industry and has set up manufacturing subsidiaries in Brazil, Poland, and India. Afterwards he worked in the private equity industry managing a portfolio of chemicals and metals investments. He holds a B.S. in Mechanical Engineering from University of California, Berkeley, and an M.B.A. from Columbia Business School.

Mary Moon, Chief Scientist for Fluitec International, m.moon@fluitec.com

Mary is a physical chemist; her doctorate is from the University of Chicago. Mary recently earned her MBA with a concentration in finance at Rider University. Her professional experience includes R&D and project management with lubricants and coatings. Tribology, electrochemistry, and statistics are among her areas of technical expertise. Mary serves as Chair of the Philadelphia Section of the Society of Tribologists and Lubrication Engineers (STLE).