[ngg_images source=”galleries” container_ids=”2″ display_type=”photocrati-nextgen_pro_horizontal_filmstrip” image_crop=”0″ image_pan=”1″ show_playback_controls=”1″ show_captions=”0″ caption_class=”caption_overlay_bottom” caption_height=”70″ aspect_ratio=”1.5″ width=”100″ width_unit=”%” transition=”fade” transition_speed=”1″ slideshow_speed=”5″ border_size=”0″ border_color=”#ffffff” override_thumbnail_settings=”1″ thumbnail_width=”120″ thumbnail_height=”90″ thumbnail_crop=”1″ ngg_triggers_display=”always” order_by=”sortorder” order_direction=”ASC” returns=”included” maximum_entity_count=”500″]

Download Brochure

Eliminate Lube Related Shutdowns, Trips and Fail-to-Starts

The following mechanical problems lead to unscheduled shutdowns:

- Sticking and seizing valves

- Overheated bearings

- Decreased effectiveness of heat exchangers

- Increased wear on valves and other components

- Shortened life of lubricant, filters and seals

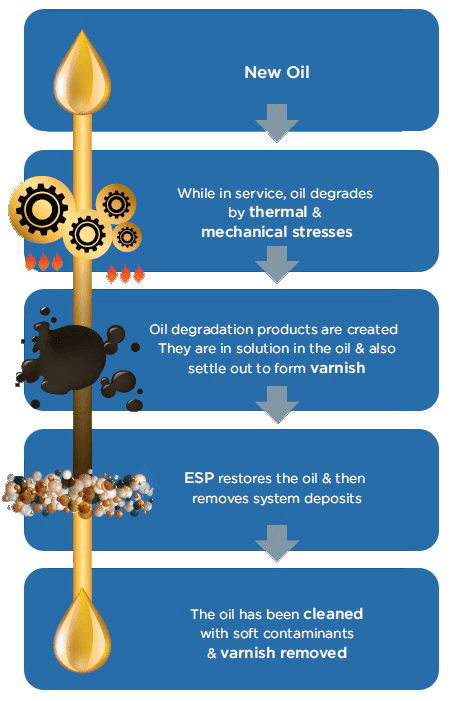

And they all have one thing in common: Varnish and Sludge

You have bigger things to worry about than free-radicals and oil degradation molecules forming and depositing in your system.

Don’t wait until you have a deposit problem which requires excessive money, time and energy to solve…

Stop varnish and sludge before it even starts

Electrophysical Separation Process™ (ESP)

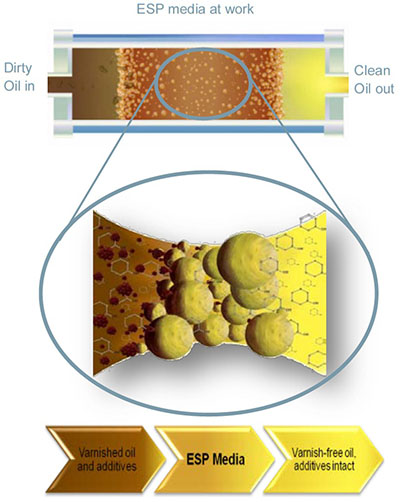

ESP technology relies on the principles of “chemisorption.” ESP selectively removes oil degradation products that are in suspension or in solution without disturbing the fluid’s additive system. For optimal performance, ESP media is fully customized for each application and is selected based on oil type and condition.

How it works: the power of selective Chemisorption

As oil degradation byproducts (depleted antioxidants and oxidized base oil) make contact with ESP media, the specific mix chemically targets and removes the contaminants through strong adsorption forces. This ensures it will not be released back into the oil. ESP has a high capacity as it uses the full volume of the media, not just surface area.

The reliable operation of our turbines & compressors is of critical importance to Siemens. Providing our customers with Fluitec’s ESP technology allows them to extend the life of their lubricant assets while improving plant efficiencies and uptime .

Siemens AG Energy Section

Siemens recommended

Siemens’ recommended technology for removing varnish-forming contaminants from turbine oils is the Electrophysical Separation Process™ (ESP).

“Siemens has seen several successful examples of this technology (ESP) applied to large and small steam and gas turbines, as well as compressors. In all cases, the varnish-forming contaminants were removed from the fluid in a few weeks”

Don’t take our word for it, download the Siemens technical article. (HINT: Check out the last pageof the document)

Download Siemens Flyer

Monitoring Oil Degradation and Varnish

The tests that provide the highest value in predicting turbine oil varnish are the individual antioxidant monitoring and Membrane Patch Colorimetry MPCin combination with particlecounting.

The earliest sign of oil degradation is detected with voltammetry (RULER method) since the antioxidants are the most reactive species in turbine oils and are the first to deplete.

The most important testto predict varnish formation is the Membrane Patch Colorimetry test, which measures the color of the sub-micron oil degradation products, as well as particlecounting.

It is preferential to use these tests together to provide a more complete picture of the varnish tendencies of the turbine oil.

“The most important test to predict varnish formation is MPC”

“The earliest sign of oil degradation is detected with voltammetry (RULER method)”

DeliveringESP to your lubrication system

ESP is easily delivered in a kidney loop system using Fluitec’s VITA ESP series of equipment. VITA ESP is designed for performance using vessel size and flow dynamics for optimum contact time with the oil to quickly and effectively remove degradation byproducts

VITA ESP III

VITA ESP II

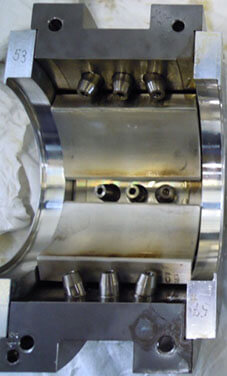

Deposits on journal bearings box

Journal bearingsafter ESP

QUESTIONS ABOUT ESP VARNISH MITIGATION?