Brochure

Learn more about how our Boost VR+ Fluid Enhancement solution can help.

Case Studies

Learn more about how our Boost VR+ Fluid Enhancement solution can help in real world situations.

Learn more about how our Boost VR+ Fluid Enhancement solution can help.

Learn more about how our Boost VR+ Fluid Enhancement solution can help in real world situations.

Integrated with Solvancer® patent-pending technology, Boost VR+ improves the solubility of the in-service hydraulic oil and as a result, varnish and sludge dissolve back into the oil. Compared to other varnish removal solutions, Boost VR+ creates a cleaner, more cost-effective way of eliminating varnish and extending the life of your machinery.

Boost VR+ reduces your maintenance costs, saves you time, and consequently, generates a bigger bottom line. Apart from effectively eliminating varnish, Boost VR+ doesn’t come with risk. While other oil varnish removal methods run the risk of machine damage, Boost VR+ guarantees a safer and cleaner way.

Sludge and varnish are the scourge of industrial plants, as they cause a multitude of problems. These deposits, whether they become a hard crust on the machine or settle as brown, jelly-like grease, interfere with the performance of the hydraulic fluid and the machine, like:

These inefficiencies cause downtime and lost revenue, while damaged equipment accrues huge repair bill. It’s imperative, therefore, that facilities remove varnish and sludge from machine systems.

To flush out the varnish and sludge from systems, many companies rely on chemical flushing, which contains detergents and dispersants. While chemical flushing is effective at removing deposits, the detergents and dispersants can damage the machine. In fact, even minuscule amounts of these cleaning agents can lead to compatibility problems and threaten the performance of equipment like your turbines or compressor oil.

Boost VR+ eliminates these worries. It’s a varnish removal solution that won’t damage your equipment or hydraulic oil.

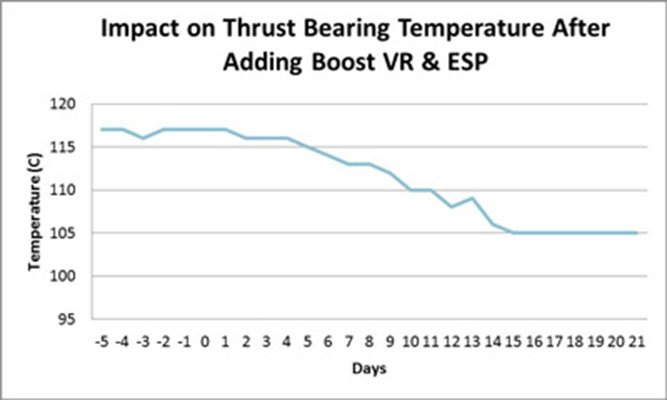

Boost VR+ works well with any ESP system, but if you want to get the most out of our varnish removal solution, use Boost VR+ alongside the Fluitec Vita ESP. This ESP system selectively removes oil degradation products from the hydraulic oil without interfering with the fluid’s additive system.

Through a process called chemisorption, strong adsorption forces take these damaging contaminants out of the fluid and ensure that they won’t be released back into the oil. The Vita ESP is ideal for critical lubrication systems, minimizing unscheduled shutdowns and ensuring operations remain cost-effective.

Learn more about the Fluitec Vita ESP technology.

Boost VR+ is used in various machine systems that generate sludge, varnish, and other contaminants. These include turbine systems, centrifugal and axial compressors, boiler feed water pumps, NSF H1 compressors, and more.

Clients have recorded impressive results. Together with Vita ESP, Boost VR+ reduced offline periods for turbines, stabilized varnish potential levels, and generated significant savings. In many cases, improvements were accomplished without an outage.

Fluitec has offices in all major regions, so you can reach out to us wherever you’re based. We serve companies in the Americas (our office is based in the USA), Europe (the Netherlands), Asia, Middle East, and Africa (Singapore), and Oceania (Australia).

Get in touch, and we’ll walk you through the capabilities of our soluble varnish removal solution.