How Long Can a Turbine Oil Really Last?

When we think about turbine oils, the first thing that typically comes to mind is, “How long will it last?” This is a great question as turbine oil sumps are usually very large, approximately 3,700 gallons or 14,000 liters. That’s almost 67 drums of oil, which is quite costly! Typically, mineral oils tend to last around 3-5 years in a turbine but this really depends heavily on the conditions that exist within the system. If the system is dirty, experiences temperatures above the threshold and creates deposits then degradation would occur at a faster rate compared to a clean system.

Turbine oils commonly experience oxidative stresses. These oxidative stresses normally result in varnish-forming deposits which cause the oil to degrade significantly. However, if the turbine oil has been engineered to remove varnish-forming deposits then the life of the turbine oil can be extended. This prolonged life will also impact positively on the life of the machine. Infinity TO was created so that there may never be the need to change your turbine oil again, it can last as long as the equipment!

Introducing Sustainability to Turbine Oils

In the past, turbine oils could not be considered sustainable. As mentioned earlier, turbine mineral oils would last for 3-5 years, then disposed of and a new batch of oil used for another cycle. However, with Infinity TO, there is no need to change the turbine oil. As such, the process of oil disposal, cleaning of the oil sump and introducing a new batch of oil are all eliminated. Infinity TO has converted turbine oil into a sustainable product.

Let’s translate these savings into the impact on the environment. For every new batch of oil that we replace, several processes have to occur before it is converted into its finished product. A regular turbine sump can hold about 67 drums of oil as stated earlier. The energy used to drill for this volume of oil, refine it and produce it into a finished turbine oil is tremendous. Quite a large volume of CO2 emissions are produced from the onset to the delivery of the product. Through the use of Infinity TO, we have eliminated the production of these harmful gases and reduced the amount of waste typically produced.

Traditionally with turbine oil changes, a lot of resources were allocated to changing out the used oil. In some cases, flushing would have been performed, the plant would have shut down and extra personnel would have been hired to assist in getting the turbine up and running. These activities are all time and resource consuming. They also amount to additional downtime which will in turn lead to loss of production. These can now be eliminated through the use of Infinity TO.

One of the major areas of concern for turbine oil users is the depletion of antioxidants. As antioxidants deplete, the oil can become susceptible to varnish and thus deposits are formed. While Infinity TO is designed to control deposits when coupled with Boost AO, the antioxidants are also replenished! Infinity TO was engineered for in-situ antioxidant replenishment and this pushes the oil to literally last as long as the equipment!

Stepping up to the Challenge

It is no surprise that these products have gotten this award. Both products eliminate harmful GHG, reduce waste and help the environment. Infinity TO in particular ensures that the user is rewarded with profitability from not having to change their turbine oil on such a regular basis. As outlined above, there are numerous costs associated with changing turbine oil and these can be eliminated through the use of Infinity TO while protecting the environment.

In fact, these products are also aligned with Fluitec’s recent B Corp Certification. As the first and only industrial lubricant company to be a certified Benefit Corporation, or B Corp, we’re part of a global movement to redefine success in business. By balancing profit with purpose, we seek to achieve higher standards of social and environmental performance, transparency, and accountability. In particular, the Fill4Life concept of extending the life of industrial lubricants and increasing equipment efficiency which directly and indirectly leads to a reduction of CO2 emissions and industrial waste is integral to our B Corp allegiance.

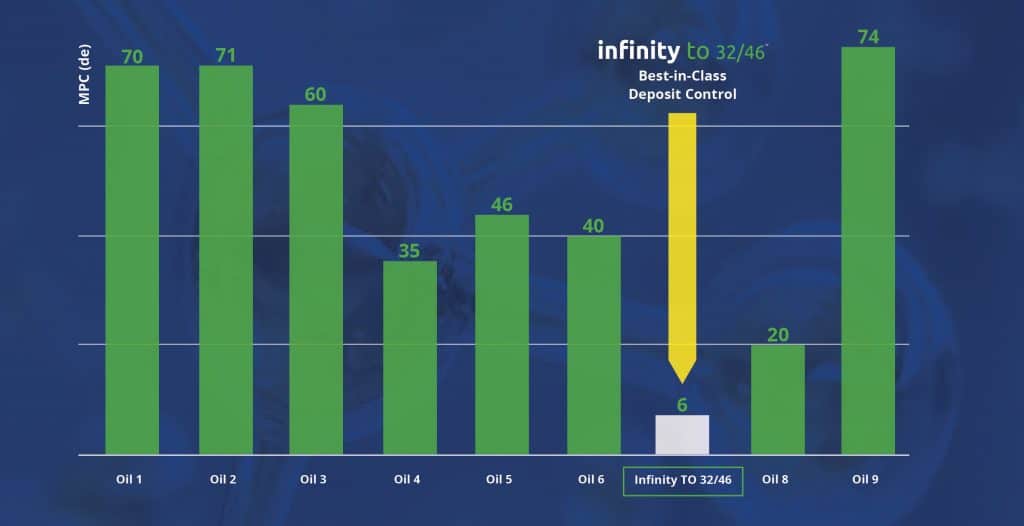

In addition to attaining the “1000 Solutions Challenge” award, Infinity TO has the best in class deposit control. As seen in the figure below, Infinity TO outperforms the competitive formulations in the market. Due to its proprietary additive system, it can capture and neutralize degradation products. This ensures that these products never have a chance to be formed in the first place! Infinity TO eliminates the need for any varnish mitigation technology and will allow your operation to sustain a long, healthy, virtually varnish free life for the machine.

Putting it to the test!

Infinity TO has been put through numerous stress tests where its RULER, MPC, RPVOT, Viscosity, Acid Number, Demulsibility, Foam and Metals were monitored. In each test, it proved its performance and generously surpassed other products. Here are some characteristics that we noted about the Infinity TO:

- Outstanding air release properties which improve valve performance

- State of the art foam suppression

- Rapid separation from water (this helps considerably if there are steam leaks in a turbine)

- Excellent filterability

- Strong rust and corrosion protection

- Compatibility with many formulations on the market (the ASTM D7155 Turbine Oil Compatibility test should always be performed prior to mixing)

- Approved by Siemens & MAN

- Meets GE, Alstom and Solar specifications

- FZG Scuffing rating of 10

- Oxidation by TOST hours (ASTM D943) is > 10,000

- Oxidation by RPVOT @150°C, minutes (ASTM D2272) is 1100 & 1200 for the Infinity TO 32 & 46 respectively

The 10 year guarantee!

At Fluitec, Infinity TO 32/46™ was created with the intention of never changing your turbine oil again. It is backed by a 10 year Deposit Control Performance Guarantee. This performance guarantee ensures that the MPC value stays within the normal range (max MPC value of 20) for at least 10 years! Additionally, there is no need for varnish mitigation equipment during the service life of the Infinity TO. There are no more performance issues on turbine bearings, servo valves, gears, hydrogen seals, heat exchangers or other equipment. This significantly reduces downtime and eliminates oils flushes. It also considerably reduces lube-oil operational problems such as trips or fail-to-starts.